By Michael Czarick

Extension Engineer – Poultry

University of Georgia

Department of Poultry Science

The effectiveness of a circulation fan system, much like a tunnel ventilation system, depends on the performance of the fans installed. In a tunnel-ventilated house, we must first install enough fan capacity to provide the necessary air exchange rate to ensure a minimal temperature difference between the pads and the fans on the hottest summer day. We also need to ensure we have enough tunnel-fan capacity to produce sufficient air speed to remove heat from the birds so they remain cool, healthy and productive.

It is relatively easy to calculate the required tunnel-fan capacity to achieve these goals. However, we will be successful only if the air-moving capacity of the tunnel fans we install matches what was used in our calculations.

A number of producers learned this lesson the hard way when the first tunnel houses were built. They believed there were minimal differences between the various 48-inch tunnel fans available, often assuming they all moved the same amount of air, used the same power and performed equally as static pressures increased.

Over time, producers learned that just because two 48-inch fans may be the same size and have the same 1- horsepower motor, it doesn’t necessarily mean they would do an equally good job of keeping birds cool during hot weather or keeping their power bills to a minimum.

Today, producers turn to test data produced by the University of Illinois BESS Labs to objectively compare tunnel fans. With independent tunnel-fan performance data, producers can be assured that their tunnel ventilation system will perform as designed from both a bird cooling and energy usage standpoint.

When it comes to circulation fans, we are back to where we were with tunnel fans 30 years ago. It is commonly assumed that all circulation fans with the same diameter can move the same amount of air. For instance, nearly identical 18-inch basket fans are reported by manufacturers to move as much as 6,360 cubic feet/minute (CFM) or as little as 1,500 CFM.

However, it is difficult to determine their actual performance because independent test data are rarely provided. Making matters worse, a circulation fan’s energy efficiency rating — CFM/watt — which will affect the size of a producer’s power bill, is also rarely reported by manufacturers or, sadly, requested by producers.

Circulation fan-system capacity

Though the science of designing a circulation fan system is still evolving, one known fact is that a circulation fan’s air-moving capacity is crucial to the system’s overall effectiveness. For instance, one key design consideration of a circulation fan system is that total circulation fan capacity should be proportional to house volume. Simply put, the larger the house volume, the greater the amount of air-moving capacity a circulation fan system should have.

Whereas in tunnel houses we talk about determining the total tunnel-fan capacity by air exchange rates and/or by the desired air speed, with the circulation fan system, we base the required circulation fan-system capacity on the percentage of house volume the system can move each minute.

Circulation fan-system mixing ability typically ranges from a minimum of 10% to an ideal of 25% of a house’s volume per minute. A circulation fan system capable of mixing 10% of a house’s volume each minute will generally help move some of the hot air off the ceiling down to bird level during cold weather, thereby increasing floor air temperatures and reducing heating costs.

Multiple field studies have demonstrated that a circulation fan system capable of mixing 20% to 25% of a house’s volume not only does a superior job of moving hot air off the ceiling during brooding but also does a far better job of thoroughly mixing the air in a house from ceiling to floor, side wall to side wall and end to end. This results in more uniform environmental conditions during the cooler times of the year.

In addition, circulation fan systems capable of mixing 20% to 25% of a house’s volume each minute have been shown to promote litter drying, thus improving bird footpad health and lowering ammonia levels. But again, as is the case with a tunnel ventilation system, these benefits will be obtained only if the circulation fans installed actually move the amount of air they are reported to move.

Air-moving capacity of an 18-inch/24-inch circulation fan

The BESS laboratory is one of the best sources for independent circulation-fan performance data. Manufacturers or individuals can submit circulation fans as they do with tunnel fans for testing.

One of the differences between exhaust- and circulation-fan testing is that a circulation fan’s air-moving capacity is generally reported as “thrust CFM” and not just “CFM.” This is because many circulation fan props are not mounted in an orifice/panel (basket fans), making it very difficult for them to be evaluated in a traditional exhaust-fan test chamber. Simply put, CFM thrust is an indirect measure of the air-moving capacity of a circulation fan, determined by measuring the force of the air coming out of the fan.

Like traditional tunnel fan testing, BESS Labs provides an energy efficiency rating of a circulation fan in terms of how much air it moves each minute (CFMthrust) with each watt of power. The higher the value, the more energy efficient the fan. For instance, if there is a 20% difference in the energy efficiency rating (CFMthrust/watt) between two circulation fans that move the same amount of air, there will be a 20% difference in operating cost between the two circulation fans.

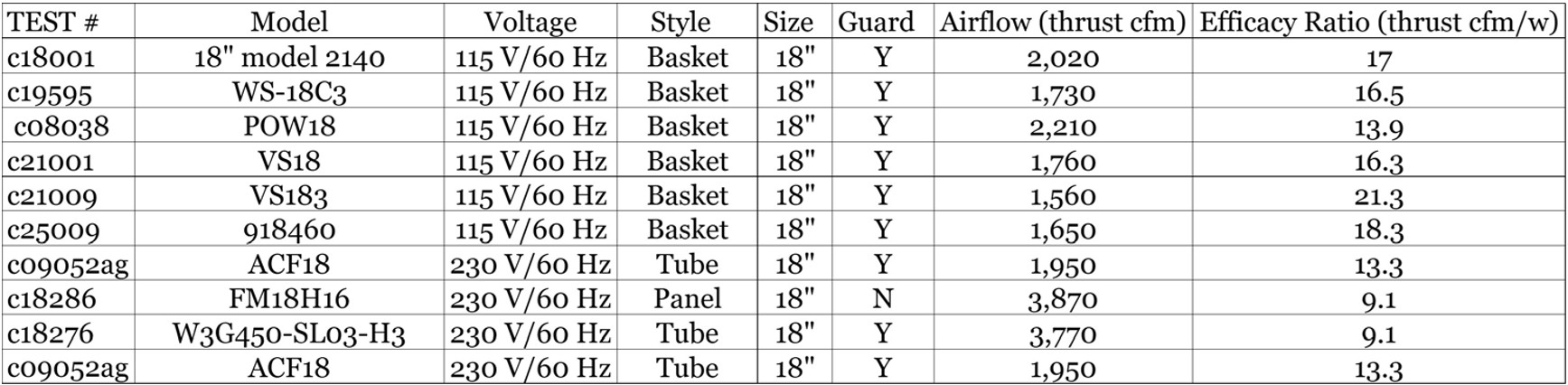

Examining circulation fan-tested data of 18-inch and 24-inch diameter circulation fans (115 and 230 V/60 Hz) published by BESS Labs illustrates just how much the performance of circulation fans can vary. For instance, the air-moving capacity of the tested 18-inch circulation fans ranges between 1,560 CFMthrust and 3,870 CFMthrust (Table 1). Variation in the air-moving capacity of 24-inch” circulation fans is even more dramatic, ranging from a low of 2,700 CFMthrust to a high of 9,260 CFMthrust, a threefold difference!

With such large differences in the air-moving capacity of circulation fans of the same size, it is clear that choosing fans based on their size rather than their actual tested air-moving capacity could result in installing a circulation fan system that cannot provide an optimal level of mixing of the air in the house, resulting in poor temperature uniformity, increased fuel usage, damp litter and high ammonia levels.

Power consumption of an 18-inch/24-inch circulation fan

The energy efficiency ratings of 18-inch and 24-inch circulation fans tested by BESS Labs show similar dramatic variations. Energy efficiency ratings range between 9.1 CFMthrust/watt and

21.3 CFMthrust/watt for the 18-inch circulation fans tested (Table 1) and between 8.4 CFMthrust/watt to 20.5 CFMthrust/watt for 24-inch circulation fans tested! With such wide variations in energy efficiency ratings, installing the wrong circulation fans could easily lead to excessive energy usage and higher operating costs.

Table 1. Performance data of 18″ circulation fans tested by BESS Labs.

Final thoughts

In conclusion, a circulation fan system’s effectiveness depends heavily on the performance and capacity of the fans installed. Just as with tunnel ventilation systems, it is crucial to select fans based on their tested air-moving capacity and energy efficiency rather than size alone.

Independent testing, such as that provided by the University of Illinois BESS Labs, offers valuable data to ensure that the chosen fans meet the required specifications for optimal performance. By carefully selecting and installing the right circulation fans, producers can achieve better temperature uniformity, reduced energy costs and improved overall conditions for their birds, ultimately leading to healthier and more productive flocks.

Editor’s note: The views expressed in this article are solely those of the author.