By Michael Czarick

Extension Engineer – Poultry

University of Georgia

Department of Poultry Science

With an increased risk of exposure to the now-endemic avian influenza virus, many poultry producers are questioning whether they should install some type of air filtration system in their poultry houses. Although on the surface this may seem like a relatively easy task, it is important to realize that preventing viruses from entering a poultry house requires far more than simply installing shade cloth or fine netting over a house’s air inlets and evaporative cooling pads.

To be truly effective in preventing or, at a minimum, dramatically reducing the likelihood of a virus entering a poultry house requires a significant amount of planning, cost and ongoing maintenance.

The following is a listing of just a few of the challenges associated with filtering the air entering a poultry house.

Challenge #1: Extremely small virus-carrying particles

An individual virus particle is a fraction of a micron and, as a result, is extremely difficult, if not impossible, to keep out of a traditional poultry house using filtration. The good news is that viruses tend to travel on larger particles that are bigger than 1 micron. Though still very small, these particles make it somewhat easier to remove viruses from the air entering a poultry house.

That being said, keep in mind that we are still talking about filtering out very, very, very small particles. We are less concerned about filtering out visible dust particles, which typically account for less than 10% of the particles in the air. Rather, our focus is on filtering out virus-carrying dust particles that can’t be seen, ranging from 1 to 10 microns in size. To provide a clear comparison, the openings in a typical window screen measure about 1,000 microns across.

Challenge #2: Poultry house tightness

A major challenge in filtering the air entering a poultry house is that even the tightest house is still relatively loose in terms of effective air filtration. For instance, consider a 40 foot by 500 foot house that can obtain a static pressure of 0.20 inches with a 25,000 cubic feet per minute (CFM) tunnel fan when everything is closed tight. Most people would consider this fairly tight, but the house has over 11 square feet of leakage area.

As a result, during minimum ventilation, about 40% of the fresh air brought in by exhaust fans enters through cracks rather than through air inlets. Although this situation is generally manageable if we are not trying to filter the incoming air, adding filters to the inlets makes the situation much more problematic. This is because it is significantly harder to pull air through filters than through cracks in a house, which can easily increase the percentage of air brought into a house through the cracks to 60% or more.

Consequently, during cold weather, when we are generally most concerned about the introduction of viruses into a poultry house, well over half of the air could easily enter unfiltered through cracks in the side walls, end walls, loose-fitting fan shutters and tunnel doors.

If filters are to be added to a house utilizing negative-pressure ventilation, it is crucial that house tightness is maximized first. Poultry houses should have a relative tightness rating of no more than 0.4 square feet of leakage per 1,000 square feet of floor area. This level of house tightness will significantly reduce, but not eliminate, the amount of unfiltered outside air entering the house through cracks if filters are added.

Poultry-house leakage area and its relative leakage area can be determined by conducting a static pressure test and using the University of Georgia Poultry411-Poultry House Tightness Calculator.

The fact is that filtering all the incoming air in a house utilizing negative-pressure ventilation is next to impossible because, no matter how “tight” the house is, a portion of the air will always enter openings in the building envelope that are not filtered. To effectively eliminate viruses from entering a house through cracks, a positive-pressure ventilation system needs to be utilized.

In a positive-pressure ventilation system, extremely powerful fans pull air through high-efficiency air filters and then push it into the house, creating positive pressure that forces air out through any cracks that may be present in a house, thereby preventing unfiltered air from entering through these cracks.

The incoming fresh air is typically distributed throughout the house using ducts, attic inlets or circulation fans. Here’s the challenge: Because essentially all poultry houses are ventilated using negative pressure, an entirely new, very powerful, energy-intensive and extremely expensive ventilation system and, most likely, a new heating system would need to be installed.

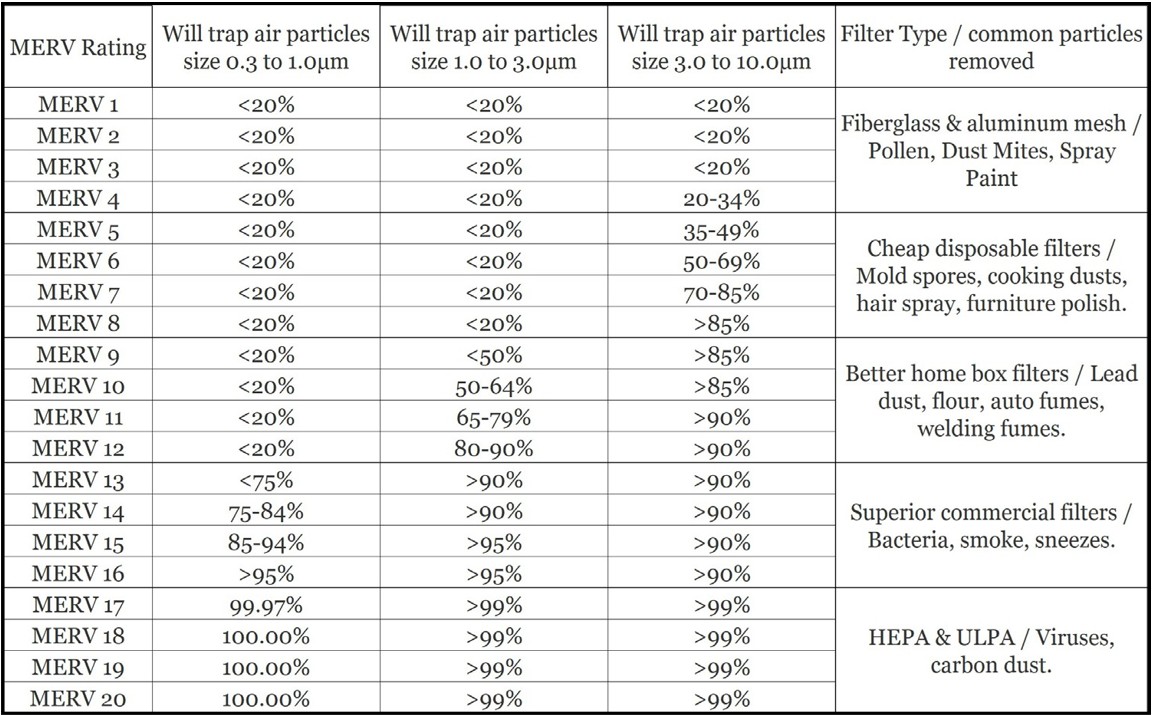

Table 1. Minimum efficiency rating values

Challenge #3: Difficulty in pulling air through filters

Air filters are classified by their minimum efficiency rating value (MERV) rating. The higher the MERV rating (1 to 20), the greater the level of filtration and the more resistive they are to airflow(Table1).

Traditionally, the US swine industry, which has relatively widespread use of air filtration, has found that MERV 14 filters are adequate for use in low-to-moderate-density/virus-risk production areas. In high-density/virus-risk production areas, MERV 15 or 16 filters are generally recommended.

To largely eliminate viruses from incoming air typically requires MERV 17+ filters (high efficiency particulate air) and a positive-pressure ventilation system (filtered air in positive pressure) with extremely powerful fans.

How difficult is it to pull air through a MERV 16 filter? Let’s demonstrate with an example. To pull air through an air inlet at a velocity of 1,300 feet per minute requires a static pressure of 0.10 inches generated by a house’s exhaust fans. To pull air through a MERV 16 filter at the same speed would require exhaust fans to generate a static pressure of approximately 1.5 inches. In other words, it’s 16 times harder to pull air through a MERV 16 filter than through a traditional sidewall inlet!

Complicating things further, prefilters (MERV 8) are typically used to increase the life of the relatively expensive MERV 15 to 16 filters, which increases the static pressure that fans must work against to pull fresh air into a poultry house. If a MERV 8 prefilter is added to the MERV 16 filter, pulling air through the pair of filters at 1,300 feet per minute would increase the pressure needed by an additional 0.5 inches, bringing the total to 2 inches of pressure! This is roughly 20 times the amount of pressure/work that poultry-house exhaust fans are typically required to pull air into a house.

Challenge #4: Relative weakness of traditional poultry-house fans

A typical poultry-house fan tends to stall when the static pressure reaches 0.25 inches to 0.30 inches. At this point, turning on additional fans does not increase the amount of airflow into a house. To lower the resistance generated by filters, the filter area needs to be greater than the inlet area upon which it is installed. The greater the filter area, the lower the air velocity through the filter and the lower the amount of pressure required to pull air through it.

It is crucial that the total pressure required to pull air through filters/prefilters not exceed 0.15 inches to 0.20 inches in a negative-pressure ventilation system. Generally, to keep the pressure at manageable levels, the filter/prefilter face velocity should not exceed 200 feet per minute; this can vary significantly depending on the type and design of air filter being used.

In other words, a minimum of 1 square foot of filter/prefilter area needs to be installed for every 200 CFM of exhaust fan capacity to be filtered. This means that the filter/prefilter area needs to be approximately four to six times greater than the inlet area upon which it is placed! The static pressure the exhaust fans are working against can be decreased further by increasing the face velocity to 150 to 125 feet per minute, but this would increase the amount of filter area required, increasing the cost of the system.

Because it is difficult to pull air through filters, it is necessary that the exhaust fans used can operate under a very high level of negative pressure. Even with a well-designed filtration system, the exhaust fans will often be working at levels of negative pressure of 0.20 inches or higher. One way to determine a fan’s suitability for use in a house with filtration is by examining its air flow ratio, which is determined by dividing its air-moving capacity at 0.20 inches by its air-moving capacity at 0.05 inches. The higher the air flow ratio, the less the fan’s air-moving capacity decreases as the pressure it works against increases.

In poultry houses utilizing filtration, it is generally recommended that they should have an air flow ratio of 0.80 or greater. Producers need to remember that, even with high-quality exhaust fans, if filtration is required year-round, a house’s exhaust-fan capacity will likely need to be increased by 20% to 30% to compensate for the loss of air-moving capacity caused by higher operating pressures.

Challenge #5: High initial and operating costs

The typical poultry house requires a ventilation system during hot weather that can provide a minimum air exchange rate of approximately 1.25 CFM per pound of birds. To minimize cost, a filtration system should be sized to have a capacity of at least 50% of this value (0.625 CFM per pound) to handle ventilation needs in winter, early spring and late fall when disease pressure tends to be at its highest.

The cost in the US of a MERV 14 filter is approximately $50 to $75 per 1,000 CFM, while the cost of a MERV 16 filter is $75 to $100 per 1,000 CFM. In either case, a less expensive MERV 8 prefilter would need to be used, increasing the cost by an additional $10 to $20 or more per 1,000 CFM of exhaust-fan capacity.

Keep in mind that these are just the costs of the filter/prefilter material and don’t include the filter housing and installation costs. Furthermore, increasing house tightness will also add a significant cost. All the cracks need to be sealed with caulk, loose-fitting end-wall and side-wall doors may need to be replaced, and socks/caps would need to be added to all exhaust fans to prevent unfiltered air from entering through them when they are not operating, which can add tens of thousands of dollars to the cost of a poultry-house filtration project.

Due to the increased operating pressures required, either older and weaker exhaust fans would need to be replaced or new fans would have to be added to offset the reduced air-moving capacity of the fans. For reference, the US swine industry has found that installing MERV 14 to 16 filtration systems increases the cost of a house’s ventilation system by more than fivefold, not including additional costs for construction and installation.

Then, of course, there are the increased operating costs. Prefilters may need to be replaced multiple times a year due to the amount of feathers and down around poultry farms. Fan belts will tend to need frequent replacement due to the strain required to pull air through air filters, which is why it is typically recommended that only direct-drive fans are used in filtered-air houses.

Care must be taken to ensure the filters are kept as dry as possible, as they will tend to become clogged with dust more quickly if wet and are more prone to damage, necessitating more frequent replacement. Then there will be increased power bills of possibly 30% or more due to the loss of fan efficiency related to operating at higher static pressures.

If you are considering installing a filtration system on a new or existing poultry house, it is imperative to consult a qualified engineer. The filter/prefilter areas, operating static pressures and ventilation system air-exchange rates provided above are only rough estimates to illustrate the overall magnitude of the challenges associated with filtering the air entering a poultry house.

Designing a filtration system for a poultry house is a complex process and must not be taken lightly. The wrong type of filter, prefilter, exhaust fan or installation method may not only dramatically decrease the effectiveness of a filtration system’s ability to prevent viruses from entering a poultry house but also significantly affect a producer’s ability to provide optimal growing conditions throughout the year.

In the end, producers often find that installing a filtration system in an existing house is extremely difficult, expensive and would rarely be as effective in preventing an airborne virus from entering a house as a new positive-pressure poultry house that was specifically designed for air filtration from the start.

Final thoughts

Ultimately, installing an effective filtration system in poultry houses is extremely difficult and very expensive. It requires a delicate balance between filtration efficiency, ventilation design and cost considerations. Although challenges such as house tightness and airflow resistance complicate the process, advanced planning and proper engineering will significantly improve the likelihood of installing an effective filtration system.

Remember that even the best air filtration system does not guarantee that a poultry producer will not experience a disease outbreak. There will always be the chance that a virus will “walk or crawl” its way into a poultry house.

Editor’s note: The views expressed in this article are solely those of the author.