By Elisangela Guaiume, PhD

Lead Nutritionist

Cargill Animal Nutrition

From volatile ingredient costs to environmental regulations and disease challenges, poultry producers are facing multiple challenges that can impact their profitability.

But of all the issues they need to react to, making sure they are providing the most profitable nutrition strategy to their birds – at a time when global feed prices have been rapidly increasing – invariably ranks high on the list.

Perhaps more than any other livestock sector, the poultry industry relies on maximizing efficiencies in the face of very tight margins. And with feed accounting for as much as 70% of an operation’s costs, it’s vital that it delivers a valuable return on investment. This is where tailored nutrition comes in.

Tailored nutrition involves formulating feeds to deliver the levels of nutrients that are needed to reach the producer’s goal without excesses.

The science of feed

Cargill’s approach to delivering tailored nutritional solutions starts with working very closely with the producer to understand their goals, challenges and limitations. Then, we leverage our experience and research findings to develop a tailored nutritional program with the proper nutrient levels needed for the producer to meet those goals.

We also focus on understanding the ingredients available. Through our research, we understand how ingredients can impact animal performance and we do that by understanding ingredient composition and utilizing data analytics to more accurately predict nutrient values.

Across the US and Canada, Cargill has 64 plants producing animal feed. Thousands of ingredient samples from those plants are sent to our laboratory in Minnesota, where they are analyzed, summarized per ingredient and supplier and added to our ingredient database. In total, we conduct about 13 million nutrient analyses annually.

We also run about 200 trials across 15 research centers, universities and third-party laboratories each year, which gives us an even deeper understanding of how ingredients and nutritional decisions can impact flocks and our customers.

Helping producers to react

Aside from making sure we estimate the nutrient values of an ingredient correctly, one of the benefits of having such a robust database is that we can spot trends in ingredients quickly and adjust customer formulas before they see an impact in birds’ performance.

For example, regular testing of one of our soybean meal suppliers throughout 2022 helped us identify significant decreases in crude protein levels in a new crop of soybean. This robust database gave us the confidence to quickly recommend that our customers adjust their formulations and ensure production is not negatively impacted, even though it led to an increase in feed costs.

Similarly, having detailed knowledge of our ingredients helps us predict nutrient values through equations and have more flexibility on feed formulation. For instance, by better predicting the energy level of corn we can potentially decrease the amount of fat in the diets or utilize with confidence more alternative feed ingredients – when available – to help mitigate the increase in feed costs.

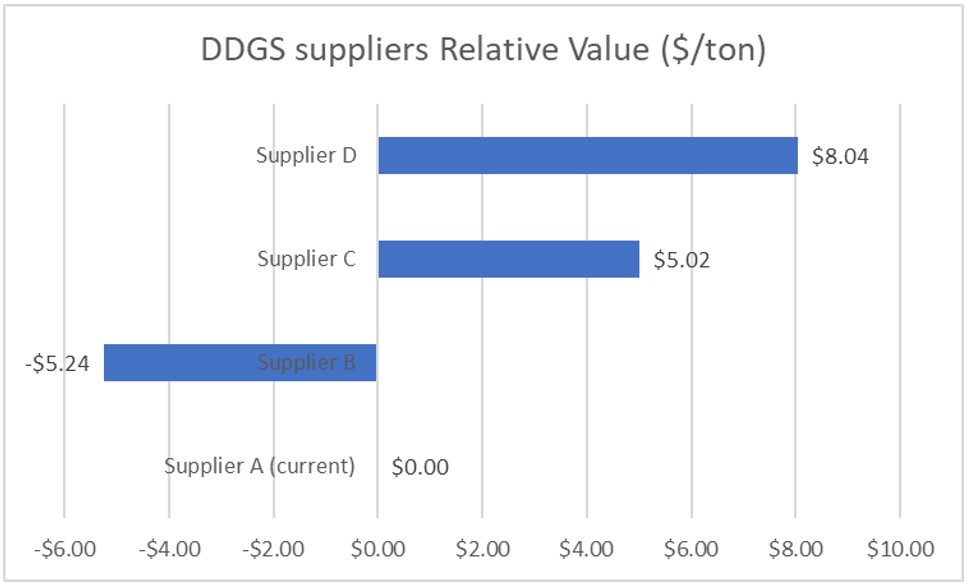

Our customers can also utilize Cargill’s data to determine which ingredient supplier can offer the best value to their formulations; one supplier was able to save as much as $8/ton by switching their DDGS supplier. (Figure 1).

Figure 1.

Following recommendations into the field

Once our nutritionists have worked with producers to implement new formulations, we then work closely with customers to help them understand how the diets have changed.

Thanks to regular visits from Cargill’s nutrition team, we also help them monitor how those changes are impacting their flock and provide follow-up support and adjustments where needed.

Ultimately, because of our close relationships with our customers we don’t just understand the problems they face, we understand exactly how and why our formulations are making a difference, and that’s what tailored nutrition is all about.

If we can help producers react to the market, as well as to what’s happening in their flocks, and help make their feed management decisions simpler, then that’s the perfect outcome.

Editor’s note: Content on Modern Poultry’s Industry Insights pages is provided and/or commissioned by our sponsors, who assume full responsibility for its accuracy and compliance.