Air pollutants in poultry houses significantly impact poultry health and production. Not only is dust a problem, but the airborne bacteria and viruses that cling to the dust pose substantial health risks.

Lingying Zhao, PhD, agriculture air quality specialist and Extension educator at The Ohio State University, discussed her insights on dust mitigation and collection during a May 2025 webinar sponsored by the University of Georgia.

Much of Zhao’s research focuses on developing effective and economically feasible management practices and technologies to mitigate air pollutants and prevent pathogen transmission.

Triple threat

She explained that dust, also known as particulate matter (PM), presents a triple threat:

- Causes respiratory illnesses

- Exacerbates existing respiratory problems

- Carries pathogens, potentially exposing birds to additional diseases.

These three threats make dust removal critical.

Zhao pointed out that bacteria adhere to airborne PM particles, allowing them to be transmitted between birds in the same or nearby houses. “Escherichia coli, Salmonella spp., Campylobacter spp., Staphylococcus spp., Clostridium perfringens, and Enterococcus spp. can be concentrated on larger dust particles, and 95% of bacteria are found on matter greater than 3.3 micrometers,” she noted. In addition, viruses attach to particles as big as or bigger than themselves.

Over the past decade, various management practices and dust and pathogen control technologies have been developed and preliminarily tested in commercial poultry facilities, with varying degrees of success. Technologies that have been applied for PM control include air filtration, impaction curtains, oil/water spraying, wet scrubbers, electrostatic precipitation and electrostatic spray scrubbing.

“Among these methods, electrostatic methods and wet scrubbing achieve high removal efficiencies for both fine and coarse PM,” Zhao said.

In the discussion, Zhao reviewed the other methods, analyzing the performance, effectiveness and limitations. She then described the potential of PM and pathogen control with current technology.

Dust control strategies

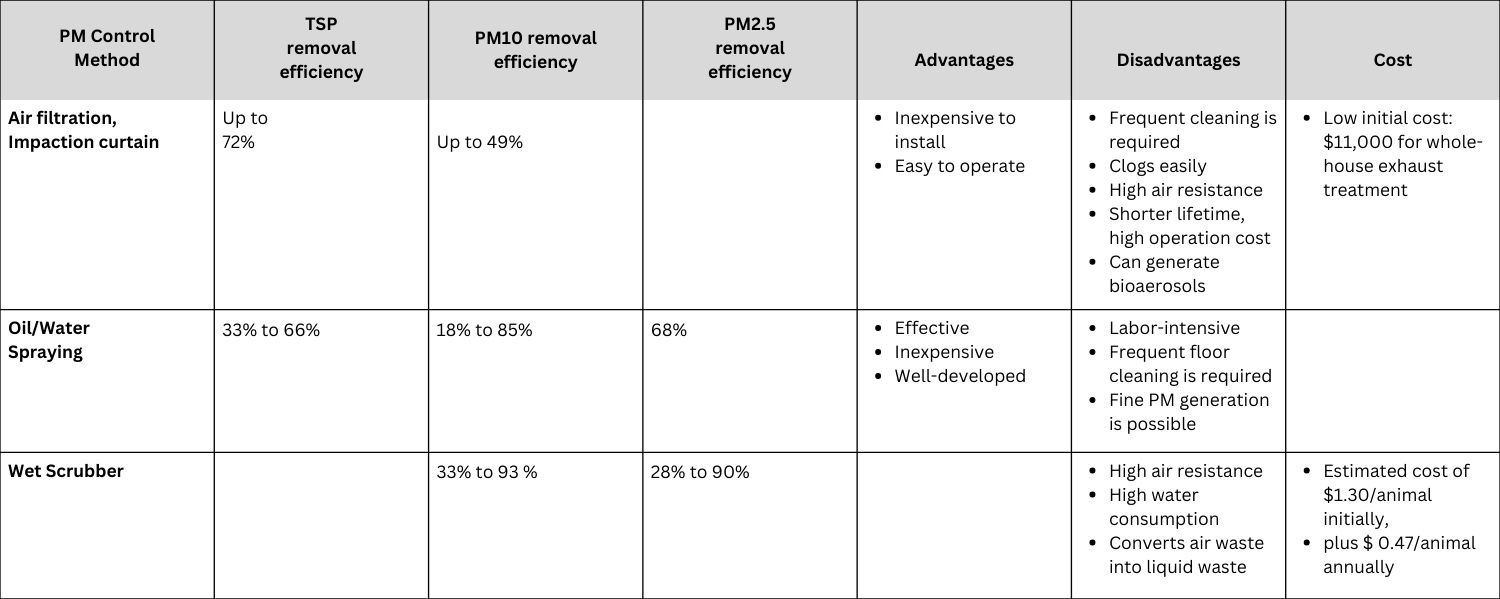

The dust control strategies Zhao discussed were air filtration and impact curtains, oil/water spraying, and wet scrubbers (Figure 1).

Air filtration and impact curtains

These devices filter dust and are inexpensive to install, but clog easily, need frequent cleaning and can generate bioaerosols.

Oil/water spraying

With oil/water spraying, droplets collide with dust, causing the PM to settle on the floor, cages and other surfaces, preventing the PM from becoming airborne again. This system is effective and inexpensive to install in houses with existing water lines, but is labor-intensive, requiring frequent cleaning of the floor and other surfaces where the dust mixture settles.

Wet scrubbers

Wet scrubbers consist of an air scrubbing column, liquid sprayers and wetted packing material. The dust-laden air passes through the column, and then the particles are collected in the packing material. Wet scrubbing technology is effective for PM removal; however, water consumption and liquid waste generation are disadvantages worth considering.

Figure 1. Dust control strategies

Airborne bacterial mitigation

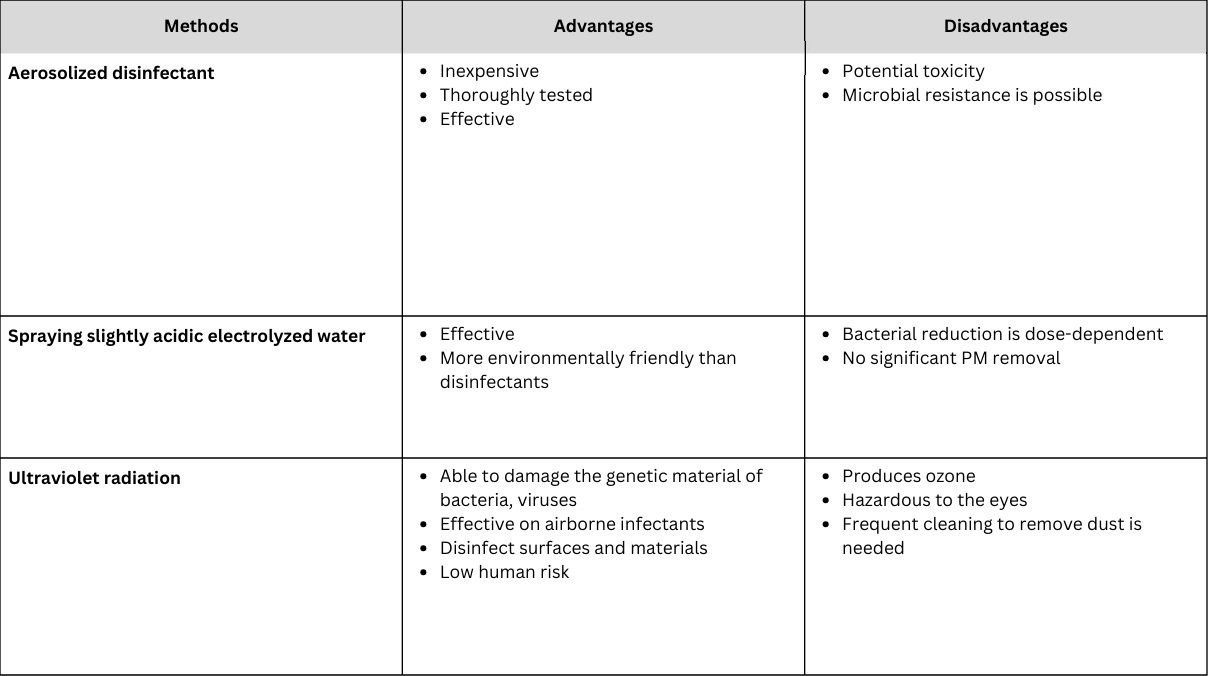

Zhao then discussed several technologies for reducing airborne bacteria in poultry houses (Figure 2).

Spraying aerosolized disinfectant

Spraying aerosolized disinfectants works by surrounding small particles. Water vapor increases the dispersion of disinfectants, making this method effective and reducing the time needed for disinfection. “The disinfectants commonly used include chlorine, ozone, ammonium salts and glutaraldehyde,” Zhao said. The disadvantages, she explained, are that microbes can build up resistance, and the disinfectants are potentially toxic.

Spraying slightly acidic electrolyzed water

In slightly acidic electrolyzed water spray systems, an electrolyzed sodium chloride solution, combined with an acid to achieve the desired pH, is sprayed through a high-pressure nozzle and evenly distributed across the house at regular intervals. Although this method can inactivate bacteria, it doesn’t remove dust.

Ultraviolet light disinfection

Ultraviolet radiation has wavelengths ranging from 200 nm to 280 nm, with the 262 nm wavelength being the most effective at inactivating bacteria and viruses and disinfecting surfaces, Zhao noted. While effective, this method requires cleaning to remove dust, is a danger to the eyes and produces ozone.

Figure 2. Mitigation of airborne bacteria

Dust, bacteria control

“Electrostatic precipitation has great potential for both PM and pathogen control,” Zhao noted.

She explained that all electrostatic systems work similarly by negatively charging airborne dust particles, which are then attracted to and deposited on grounded collector plates and surfaces like the walls, floors, ceilings or sprayed droplets.

“This method inherently overcomes the clogging and high air resistance problems that are common in other dust control systems,” she explained.

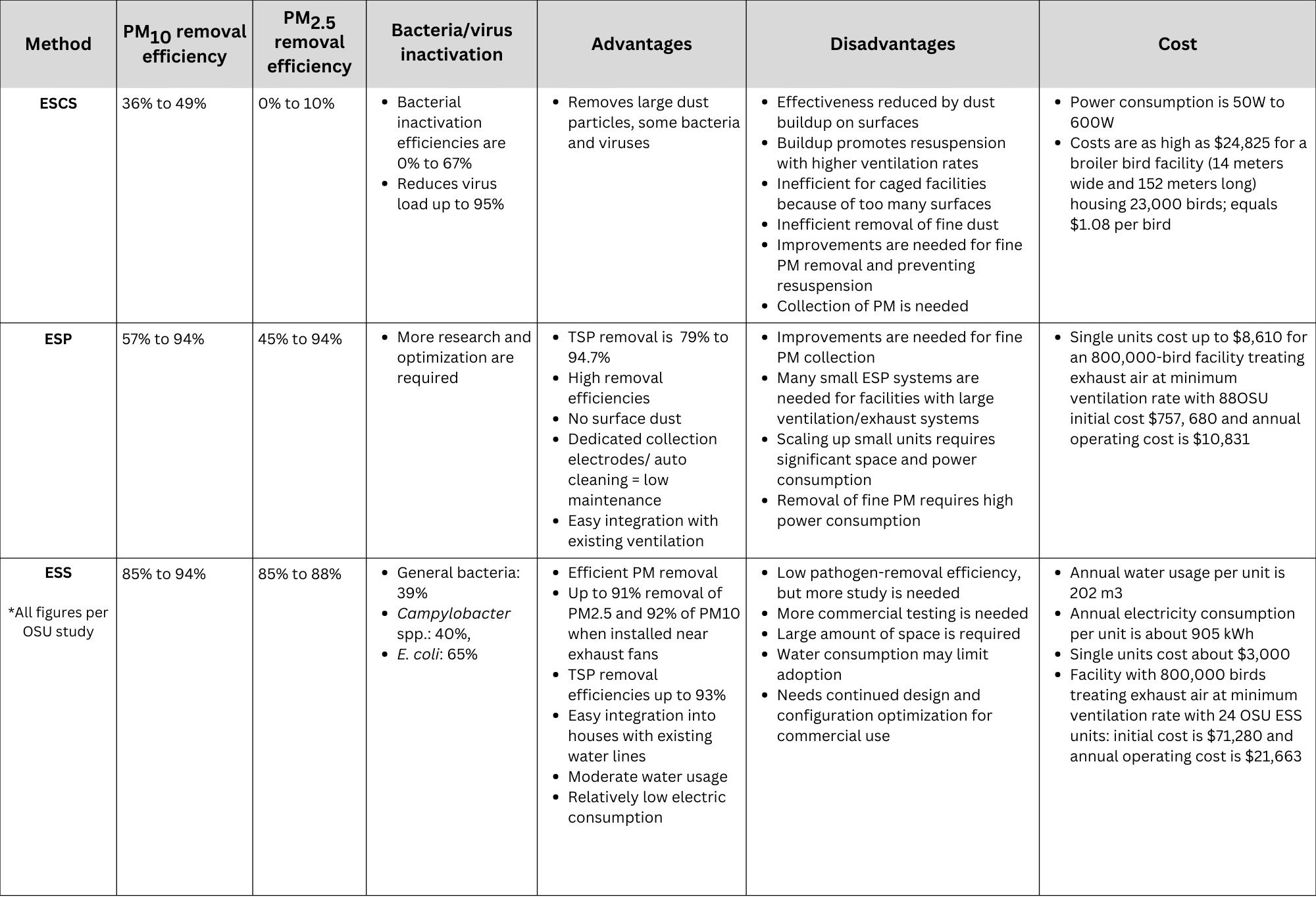

Three types of electrostatic precipitation are used in poultry houses: electrostatic space charge systems (ESCS), dry electrostatic precipitation systems (ESP) and wet electrostatic systems or scrubbers (ESS) (Figure 3).

Electrostatic space charge systems

Zhao explained that houses with ESCS have long wires with many spike-like discharge electrodes running the length of the facility. These are high-voltage wires while nearby surfaces — roof, walls, and ceiling — are grounded. The charged airborne particles fall, collecting on surfaces.

ESCS systems can efficiently remove dust, bacteria and viruses, improving indoor air quality and potentially improving bird health. However, the dust that builds up on surfaces can be resuspended, exposing birds and workers to hazards.

“The relatively low-cost, commercial availability and ability to control dust make this system appealing,” she said. However, “the ESCS needs dust collection capabilities to prevent resuspension.”

Dry electrostatic precipitation systems

ESPs take it a step further, utilizing charged collection plates or wires to collect dust, allowing it to be removed from the house.

“The ESP systems show promise due to the removal of PM and bacteria, but further optimization is needed to increase pathogen control and reduce costs,” Zhao stated.

Electrostatic scrubber

In this method, charged water droplets are sprayed, attracting airborne particles. This water and dust mixture is collected in storage tanks so that the dust is completely removed from poultry houses.

Zhao’s research demonstrated that ESS is relatively inexpensive, easily installed in poultry houses with water lines and doesn’t require excessive cleaning or maintenance. Her work also revealed that ESS represents a promising technology that efficiently removes large and small PM. She noted that more studies are needed to determine the system’s effectiveness in mitigating bacteria and viruses, as well as to conduct more on-farm testing.

Figure 3. Electrostatic precipitation methods of dust and pathogen control

ESCS: Electrostatic space charge systems; ESP: electrostatic precipitation systems; ESS: Electrostatic scrubber; OSU: The Ohio State University; PM: particulate matter; TSP: total suspended particulate.

In conclusion

Zhao believes that the best methods for controlling dust and pathogens within poultry houses are electrostatic precipitation systems, which enhance indoor air quality and improve the health of birds and workers by collecting and removing these hazards.