By Anna Fickler, PhD, Global Technical Product Manager

BASF SE

Arne Solbak, Senior Scientist

BASF Enzymes LLC

Roland Staff, PhD, Team Lead Formulation Feed Enzymes

BASF SE

Exogenous feed enzymes are commonly used in commercial monogastric diets to enhance nutrient and energy digestibility of the diets by reducing the impact of antinutritional factors and/or releasing additional nutrients.

Often, only performance and digestibility studies are considered important to prove the benefit of dietary enzymes in poultry and other animals. Many of these studies use freshly produced product samples that were stored under optimal conditions. However, less focus is put on the commercial conditions that impact enzyme stability during storage, premixing and pelleting.

In many countries, humid and hot climate conditions can lead to loss of activity in enzyme products, especially if storage under ambient conditions is not consistently possible.

In addition, enzymes are sensitive to pH and temperature during application and have specific optima for these parameters. If the pH or temperature is too extreme, the enzymes can become inactive, reducing or eliminating their effectiveness in breaking down feed components.

Moreover, not all enzyme molecules can withstand the acidic conditions in the stomachs of monogastric animals, thereby losing activity before they can hydrolyze the antinutritional factors.

If the animals do not receive the intended enzyme dose with their feed due to the factors mentioned above, or if the enzyme is not optimally adapted to the gastrointestinal conditions of the animal, it can lead to inconsistent or even negative effects on animal performance.

Fundamental understanding

Selecting an effective feed enzyme requires a fundamental understanding of protein structure, function and stability when exploring enzyme diversity and how these attributes can enhance application efficacy.

Generally, enzymes are illustrated as complex static molecules. However, this is far from the truth because they are dynamic structures that have tremendous movement and are regarded as stable if in a balanced energy equilibrium.

External forces such as temperature, harsh pH conditions and oxidative stress can disrupt the equilibrium, leading to perturbations that unfold the protein structure and result in a loss of biological function. Therefore, selecting the right feed enzyme requires consideration of both in vivo studies and product characteristics, such as overall stability of the product and its fit to the conditions within the animal’s gastrointestinal tract (GIT).

Additionally, it’s important to remember that enzymes are not delivered “as is” to the customers; they are formulated together with carriers or formulation aids into final solid or liquid products that can be added to the feed production process.

Understanding enzyme stability

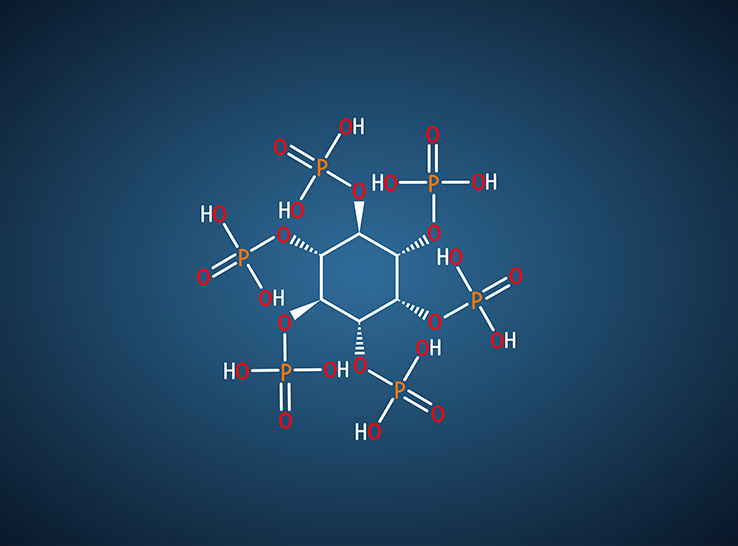

The stability of an enzyme is based on the sequence of the amino acids and their interaction with other surrounding amino acids. Amino acids have different functional groups that enable the polymer to fold into secondary structures such as α-helixes and β-sheets, as well as unstructured free loops (Figure 1).

Figure 1. α-helixes are the red ribbons and β-sheets are the yellow arrow ribbons; the unstructured free loops are in green.

Finally, the tertiary structure of the enzyme is the combination of the secondary structures, based again on the intramolecular forces within the amino acid polymer, salt linkages, hydrogen bonding, disulfide linkages, hydrophobic interactions and Van der Waals’ forces, resulting in the functional enzyme. If these complex structures are permanently changed, the enzyme may lose its activity and function.

One main factor changing the enzyme structure, and thus stability, is temperature. Temperature triggers movement of molecules. With increasing temperatures, they move faster, which can lead to permanent structural changes. Designing an enzyme in a way that it has a rigid structure is therefore beneficial for its thermal stability. However, at the same time, enough flexibility in amino acid chains constituting the enzyme needs to be ensured, as enzymes often need to slightly rearrange themselves when delivering their function.

In nature, enzymes have evolved over the last 4 billion years. Ancestral sequences have shown that protein stability has changed over eons.

For example, during hotter eras, flexible loops between secondary structures evolved to be shorter to maintain structural rigidity compared to cooler eras, when these loops were extended to enable more plasticity in protein structure to enhance functional activity. When it comes to nature and industrial enzymes, there is a fine line between protein rigidity for stability and protein plasticity for functional activity. In the BASF lab, using directed evolution, thermal-stabilizing mutations are tested for activity in the intended application to ensure that performance is not compromised.

The activity of the enzyme is based on amino acids in the active site that can draw in the substrate, catalyze the biochemical reaction and then remove the newly formed substances to allow the reaction to repeat. The activity is enhanced by the flexibility of the active site pocket (area of the enzyme into which the substrate binds). This flexibility can be influenced by temperature and pH. In addition, pH can change the charge and shape of the substrate and affect the protein kinase A of the catalytic amino acids to enable functionality.

Several factors determine an enzyme’s gastric stability, including its resistance to both pH changes and proteolytic degradation. Thermostable enzymes (natural or evolved) often demonstrate gastric/acidic pH stability as well as enhanced shelf-life stability. This suggests that these different external forces may have a similar impact on the properly folded enzyme.

In addition, it is hypothesized that naturally or evolved thermophile enzymes tend to be more protease-stable than mesophile enzymes because the protein structures are more compact. This is due to the stronger intramolecular forces in thermophile enzymes that prevent the protease from accessing the amino acid polymers easily and initiating their degradation.

As mentioned earlier, enzymes are usually not sold as pure molecules but are rather embedded in formulations. The chemical nature of the formulation aids is also important as they can influence the effectiveness of the enzyme — negatively or positively.

For example, metal ions can help stabilize the three-dimensional enzyme structure and thus increase thermostability. On a larger scale in particular, solid formulations reduce the mobility of the amino acid chains and thus also increase stability.

In these situations, different particle sizes can impact the stability differently. Usually, larger particles (or granules) allow for higher enzyme stability than smaller, powder-like particles. In addition, it can make a difference if an enzyme is embedded in a particle or is present only on its surface.

Also, the formulation — the way it is prepared and its constituents — determines many important application parameters such as flowability, dustiness and tendency to cake. As BASF has formulation expertise from many different fields, these general application parameters and feed-specific ones can be considered and applied to existing and new products such as Natupulse® TS.

Thermostability of enzymes

Roughly 50% of the total volume of feed for poultry and pigs worldwide is pelleted. Pelleting can prevent separation of feed ingredients, improve starch digestibility and increase the animals’ energy consumption. In addition, some compound-feed producers use very high pelleting temperatures to reduce the microbial load (e.g., Salmonella) in the feed. High pelleting temperatures are a challenge for enzymes and other feed additives.

On the one hand, a feed enzyme should be most efficient under the body temperature of monogastric animals (~ 38° C to 41° C or 100.4° F to 105.8° F). On the other hand, it should withstand high pelleting temperatures of 85° C (185° F) and above.

This wide temperature range often cannot be covered by a molecule. If an enzyme is not heat-stable, the free energy within the molecule increases with increased temperatures, reaching a point where the enzyme will lose its secondary features. This results in a collapse of the tertiary structure and, thus, loss of enzyme activity.

Several techniques can be applied to avoid activity losses during pelleting. Granulation can, to a certain degree, protect the enzyme from denaturation at high pelleting temperatures. Furthermore, enzymes can be applied as liquid formulations via a post-pelleting liquid-application system.

Thus, the part of the pelleting process with high temperatures is bypassed. However, some enzymes can even retain their activity at high pelleting temperatures without granulation. These enzymes are intrinsically thermostable, either by nature or by directed evolution in the lab.

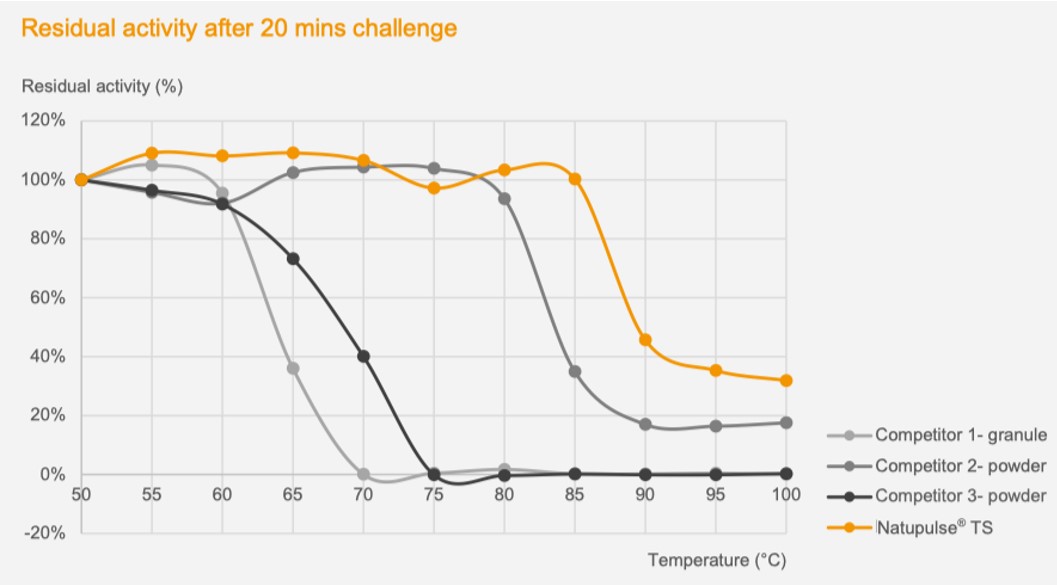

For a better understanding of the thermostability of an enzyme at high temperatures, a temperature challenge test can be conducted in vitro. In this test, the enzyme is exposed to different temperatures for 20 minutes. This evaluation does not reflect commercial pelleting processes but gives an indication if an enzyme can withstand challenging temperatures.

BASF tested Natupulse TS under these conditions in comparison to three established competitor products (one granule, two powder formulations) on the market (Figure 2). Investigators analyzed the relative activity of all enzymes after 20 minutes at temperatures between 50° C and 95° C (122° F and 203° ), with a stepwise increase of 5° C (41° F), respectively.

Two out of three competitor products showed a greater loss in activity already at temperatures above 65° C and 70° C (149° F and 158° F), respectively. At 85° C (185° F), only Natupulse TS was able to retain most of its activity. Even after 20 minutes at 90° C (194° F), almost 50% of the activity of Natupulse TS remained, showing a superior thermostability in this test.

Intrinsic thermal stability of a molecule often indicates rather low degradation during storage. Accordingly, one can estimate that such high thermostability compared to other mannanases will also lead to good shelf-life stability.

Figure 2. Heat challenge. Enzymes were diluted and heat-challenged at desired temperature for 20 minutes. The heat-challenged samples were cooled down and assayed at 50° C (122° F) in a DNS mannanase activity assay. Relative activity was calculated by comparing it to 50° C reference.

Shelf-life stability

After production of an enzyme product, a slow aging process starts decreasing enzyme activity. This process is influenced by the intrinsic stability of the enzyme, its formulations, the packaging of the product and the storage conditions.

Natupulse TS has a shelf life of 24 months when stored at or below 20° C (68° F). BASF guarantees this shelf life based on extensive testing with miniature versions of the original packaging, consisting of a bag-in-box system. The packaging material was selected to allow both excellent protection and easy use by the customer.

Careful design of logistics ensures that the enzyme’s activity is maintained through transports and that the customer receives a product that fulfills defined quality requirements. After arrival at the customer, cooled storage might not always be possible.

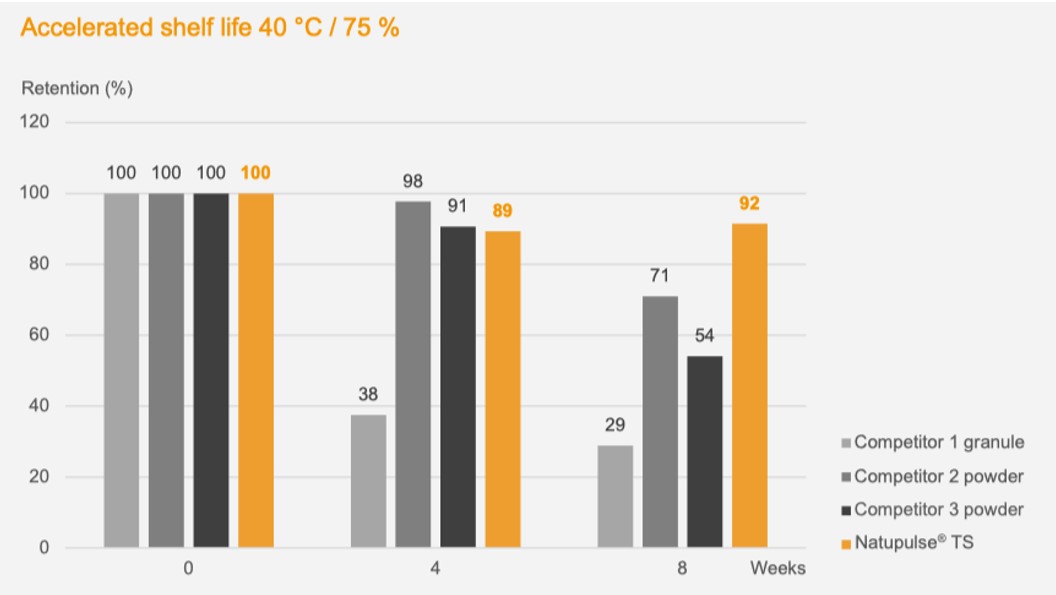

Depending on the climate, temperature and especially humidity can be high, accelerating enzyme degradation. To consider different climate conditions, BASF conducted various stability tests at different moisture and temperature levels to evaluate the performance of Natupulse TS, e.g., under so-called challenging conditions such as 40° C (104° F) and 75% humidity.

Natupulse TS was tested under these challenging conditions over 8 weeks compared to other mannanase products available on the market (Figure 3). The following graph shows that a loss in activity occurred from day 0 to week 4 for all mannanase products. However, after 8 weeks, no additional losses occurred for Natupulse TS, and its activity remained stable.

Compared to other mannanase products evaluated in this test, Natupulse TS showed superior stability after 8 weeks when stored under challenging conditions. This correlates well with the results of the pelleting stability and is caused by the enzyme’s inherently high thermostability. Additionally, the formulation design and packaging protect the enzyme from degradation.

Figure 3. Accelerated shelf-life test. Enzymes were stored for 8 weeks at 40° C (104° F) and 75% humidity. Retained enzyme activity was analyzed at 4 and 9 weeks, respectively.

Premix-stability test

Premixes are composed of manifold additives that are usually included in the feed in minor amounts. Some premixes contain vitamins, (trace) minerals, amino acids, choline chloride and enzymes, among other additives.

Some of these additives are chemically quite aggressive and can modify the enzyme molecule, for example, by perturbing the hydrogen bonds and Van der Waals’ forces, either by oxidation or even by breaking the main amino acid chain (hydrolysis) or disulfide bonds that add to the tertiary enzyme structure.

In addition to the chemically challenging environment, the same thermostability factors as with shelf life also play a role in premix stability. However, in contrast to shelf life, higher temperatures will accelerate chemical reactions in a premix even more.

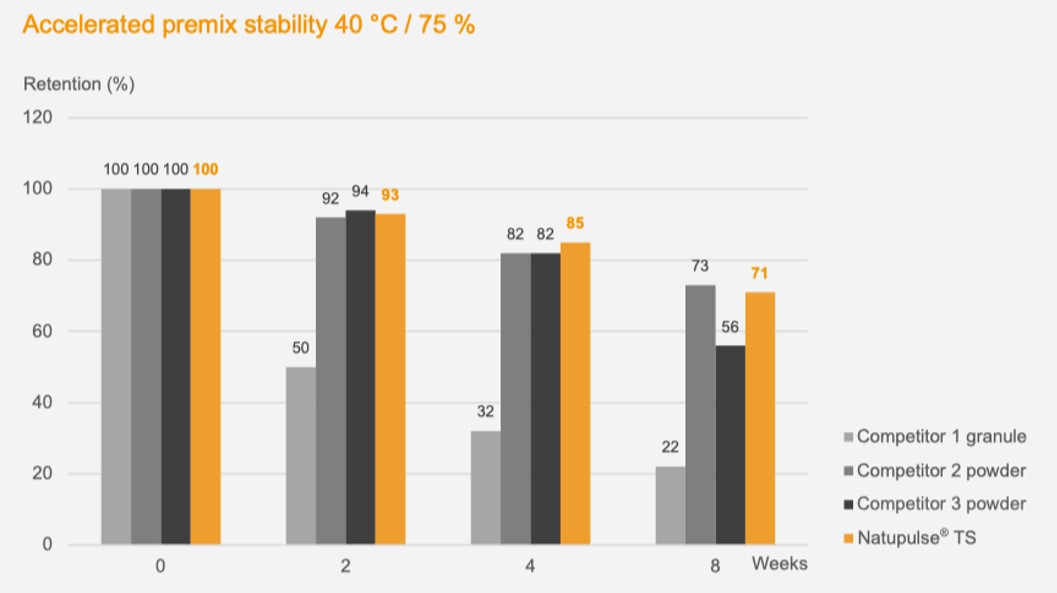

Prior to being added to the feed, premixes are usually stored for weeks or even months. Therefore, stability of the enzyme in premixes is paramount and normally ensured by specific formulation.

Granulation of the enzyme can be a technique to improve enzyme stability in premixes because the outer layer of the granule protects the enzyme from direct contact with vitamins and minerals. However, some enzyme molecules have higher stability toward chemical changes; thus, a granulated formulation is not needed.

As with the shelf-life test, BASF evaluated the stability of Natupulse TS in premixes under challenging conditions (40° C/104° F and 75% humidity) versus other mannanase products (Figure 4).

The test was conducted over 8 weeks. After 8 weeks, only one competitive product showed a similar stability as Natupulse TS. The other mannanase products had lost more of their enzyme activity, one of them up to 78% compared to the activity on day 0.

Figure 4. Accelerated premix stability test. Enzymes were stored for 8 weeks at 40° C (104° F) and 75% humidity in a commercial premix. Retained enzyme activity was analyzed at 2, 4 and 8 weeks.

Gastric stability and pH profile

For feed enzymes, the desired attributes are high efficacy on the substrate of interest with a broad pH profile and high intrinsic-protein stability. Gastric stability is important for feed enzymes because it helps ensure that the enzymes remain active until they reach their target site in the digestive tract.

Most feed enzymes such as phytase, xylanase and mannanase need to eliminate the effect of anti-nutritional factors. For that, feed enzymes need to be active already at the beginning of the GIT in an acidic environment.

The pH range of a feed enzyme is important because it affects the enzyme’s activity and efficiency. Enzyme activity is highest within a specific range of pH values, known as the enzyme’s optimal pH range. If the pH is outside of this range, the enzyme’s activity and efficiency can be significantly reduced.

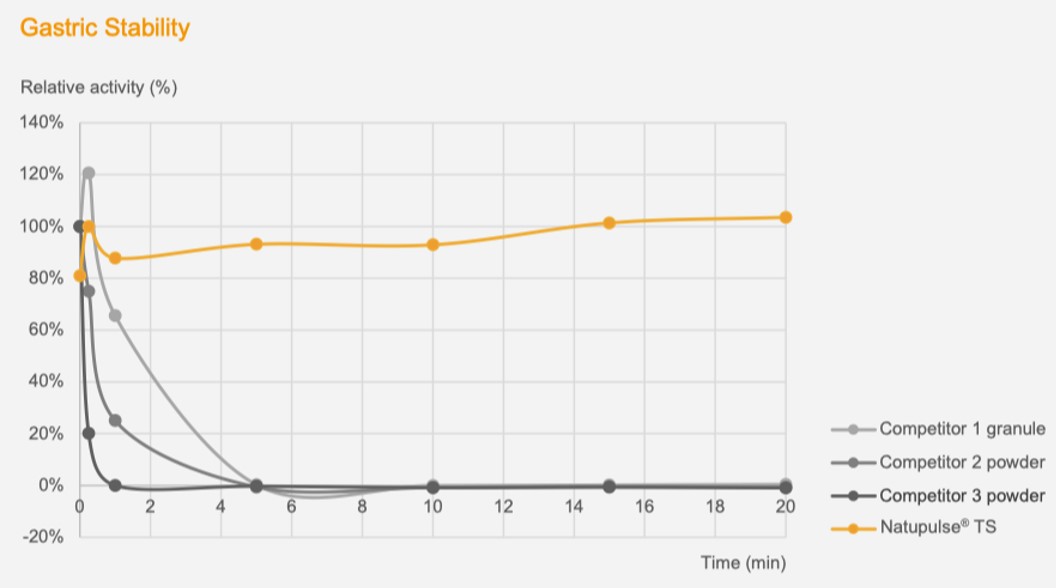

As previously mentioned, feed enzymes should be active directly at the beginning of the GIT to hydrolyze anti-nutritional factors and reduce their potential negative effects on the diet’s nutrient digestibility and nutrient absorption. In monogastric animals like poultry and pigs, the pH at the beginning of the GIT is usually between 2 and 6. Thus, a feed enzyme should ideally act under a wide pH range between pH 2 and pH 6.

Investigators also evaluated the pH range of Natupulse TS and mannanase products on the market (Figure 5). Natupulse TS has a pH range from pH 2 to pH 6 and thus is very well adapted to the pH range of the GIT of monogastric animals.

To be active at the beginning of the GIT, the enzyme needs to be available. This can be challenging in granule formulations that are fat-coated because these granules often do not dissolve fast enough. In these situations, the powder formulation of Natupulse TS is advantageous because the enzyme molecule dissolves very fast under GIT conditions and thus enables a high efficacy (Figure 6).

Figure 5. pH activity test. Extracted enzymes were diluted in H2O. Britton-Robinson buffer pH 2 to pH 11 was used. Samples were analyzed with a DNS assay at 50° C (122° F). Relative activity was calculated by comparing it to the maximal activity for each enzyme.

Figure 6. Simulated gastric stability test at pH 2 with pepsin and 37° C (98.6° F) reaction temperature. Samples were taken at desired time points and run with a DNS activity assay.

Conclusion

BASF developed Natupulse TS, an intrinsically stable mannanase, for the feed-additive market. The results confirm that this stability has an advantage in pelleting, shelf life, premix and gastric stability. In addition, the broad pH range will enable the enzyme to be active and stable in the digestive tract where it is eventually degraded by the animal’s proteolytic enzymes.

Editor’s note: Content on Modern Poultry’s Industry Insights pages is provided and/or commissioned by our sponsors, who assume full responsibility for its accuracy and compliance.