Coccidiosis doesn’t just lurk in poultry houses — it thrives there. Left unchecked, it sabotages gut health, stunts growth and opens the door to costly secondary infections.

Coccidiosis doesn’t just lurk in poultry houses — it thrives there. Left unchecked, it sabotages gut health, stunts growth and opens the door to costly secondary infections.

For decades, producers have relied on synthetic anticoccidials and ionophores to keep it in check. But with growing resistance and increasing pressure to reduce antibiotic use, more operations are turning to vaccination as a sustainable, effective alternative.

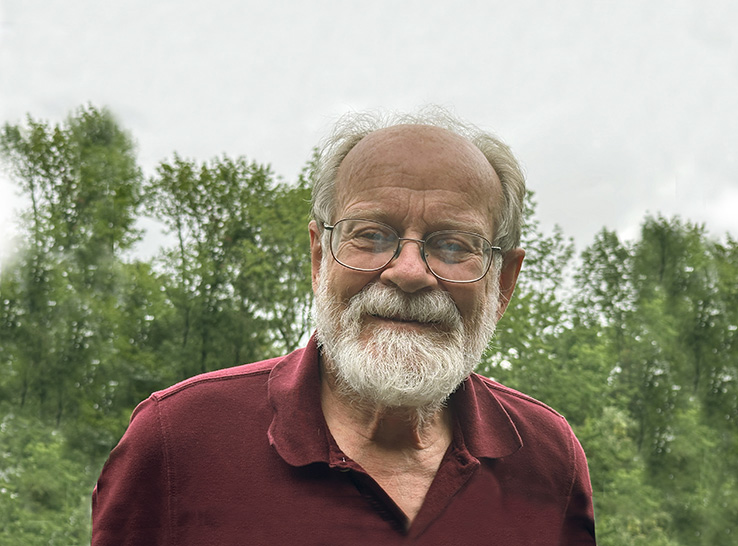

According to John McCarty, DVM, MAM, DACPV, a field veterinarian with Boehringer Ingelheim, making vaccination work isn’t just about swapping products — it requires a shift in mindset and management.

Here, Dr. McCarty draws on decades of field experience to explain why vaccination has stood the test of time, what it takes to make it work and how producers are using it to gain long-term control over coccidiosis.

Q: Coccidiosis vaccinations are nothing new, but they’ve seen an uptick in use in recent years. What’s behind this trend?

A: One major factor is resistance to anticoccidials. With both ionophores and chemicals, we’ve seen strains become less sensitive over time. But the vaccine strains we use today — some dating back to the 1950s — still work because the parasite population has proven to be very stable. What’s really moving the needle, though, are the results from producers who’ve gone all-in on vaccination.

Q: Tell us more about the experience of producers who are successfully using vaccines exclusively.

A: The organic sector tells an interesting story. These producers don’t have the option to use ionophores or chemicals — it’s vaccine or nothing. And what we’ve seen is that, after several consecutive vaccinated flocks, many reach a point where coccidiosis stops being a nagging problem. Some have been vaccinating the same farms for five to ten years now without rotation, and their lesion scores are often better than conventional operations using traditional feed additive programs.

Another group having success is producers facing resistant field strains. By vaccinating consistently, they’re essentially hitting the reset button on their Eimeria population and diluting resistant wild strains with sensitive vaccine strains. This has helped restore sensitivity to the feed additive programs while extending their usefulness when used strategically.

Q: What’s the key to the success of these coccidiosis vaccination programs?

A: There are three key elements to any successful vaccination program that make up what we call the “triad” of bird immunity: healthy birds, proper vaccine management and good husbandry. The vaccine can’t compensate for poor chicks or improper brooding any more than perfect conditions can fix bad vaccine application. Successful producers treat it as a system —they match strong chicks with precise hatchery application and follow through with proper turnout timing and litter management. That consistency is what builds lasting control.

Q: What are some of the most common mistakes you see with vaccination?

A: Thinking it’s all about the hatchery, but the fact is that hatchery application just gets things started. The real immunity develops in the house through repeated litter exposure. With precocious vaccines, the oocysts start cycling quickly — we typically see peak shedding around day 5. If you turn birds out before day 7, you interrupt that first critical cycle. The chicks haven’t had enough time to properly shed and spread the vaccine strains in their immediate environment. Waiting until day 7 allows the vaccine cycle to fully establish in the birds’ environment, creating the foundation for uniform immunity through natural re-exposure.

The other big mistake is cleaning out houses too often. Built-up litter helps maintain those vaccine strains between flocks. Some producers even reapply vaccine to fresh litter after cleanouts to get things started properly.

Q: One concern with coccidiosis vaccination is gut health disruption. How can producers manage this?

A: Most coccidiosis controls — whether ionophores, vaccines or even some chemicals — cause some degree of gut disruption. The key is timing it right. We want cycling to happen early, ideally before 23 days, so the gut heals before necrotic enteritis and other enteric diseases pop up. Precocious vaccines help here because they cycle faster. But management matters too. Good brooding, immediate feed access — all those basics make a difference in how birds handle it.

Q: Let’s talk more about management — how does this affect vaccination success?

A: People get so focused on the vaccine itself that they forget how much those first few days in the house matter. I’ve walked into too many operations where they’ve got perfect hatchery application, then drop the ball on basic brooding. The birds need three things right away: heat at their level, feed they can reach and water that’s easy to find. When these basics aren’t right, the chicks get stressed right when they should be developing immunity.

There’s a reason the best growers I know spend those first 48 hours practically living with their birds. They’re watching behavior, listening to the flock and making tiny adjustments. It’s not fancy; just old-school husbandry. But when you get it right, you can see the difference all the way to processing.

Q: Any final advice for producers considering vaccination?

A: Stick with it. The first few flocks might need some extra attention, but by the third or fourth cycle, it just seems to start flowing. That’s when you’ll see the real payoff: consistent control without the rollercoaster of resistance issues. The producers who succeed long term treat vaccination as a marathon, not a sprint. They focus on the fundamentals — healthy chicks, proper application and solid house management — and let the program build on itself over time.

Editor’s note: Content on Modern Poultry’s Industry Insights pages is provided and/or commissioned by our sponsors, who assume full responsibility for its accuracy and compliance.