By Michael Czarick

Extension Engineer – Poultry

University of Georgia

Department of Poultry Science

Although “sustainability” may seem to be a relatively new concept, the poultry industry has been quietly implementing sustainability practices for decades. The objective has always been to continually improve the conditions for our birds while simultaneously improving the energy efficiency of our poultry houses.

The following are just a few of the ways that poultry producers have improved the sustainability of providing the public with affordable poultry products.

- Partial-house brooding: By keeping the birds in a portion of the house for the first week or two, heating costs have been reduced by between 10% and 30%.

- Dropped-ceiling houses: Open-ceiling houses were a relatively common site 30 years ago, but they are becoming increasingly rare. The primary reason is that dropped-ceiling houses have 10% to 30% lower heating costs than open-ceiling houses due to a combination of reduced leakage, higher insulation levels and lower surface area. In addition, dropped-ceiling houses can produce 10% to 25% more air speed using the same number of tunnel fans due to their reduced cross-sectional area.

- Built-up litter: In the early 1980s, it was fairly common for all the litter to be removed after each flock and replaced with fresh pine shavings. Today, the bedding material is typically reused for multiple flocks. Not only has this proven to be beneficial when it comes to broiler performance, but it has also dramatically decreased the use of pine shavings, which have become a valuable natural resource.

- Litter treatments: Litter treatments allow producers to keep heating costs to a minimum during brooding by limiting the ammonia production of built-up litter. Without litter treatments, ventilation rates would have to be doubled or tripled during brooding to keep ammonia at acceptable levels, leading to drastically higher heating costs.

- Totally enclosed housing: Whereas 30 years ago most broiler houses were curtain-sided, virtually all new broiler houses, as well as those that were previously curtain-sided, are now totally enclosed. The increased insulation value and tightness of a totally enclosed sidewall have proven to reduce heating costs by 30% to 50%.

- House-tightness guidelines: Producers typically check their house tightness by regularly conducting a negative-pressure test. For the test, an exhaust fan or two is turned on in a closed-up house, and the resulting static pressure is measured. Most houses can generate a static pressure of at least 0.15” when operating 1 cfm per square foot of floor space of fan capacity.Thirty years ago, producers would have often struggled to obtain a static pressure of just 0.05” to 0.10”, indicating that the house has approximately twice the leakage area compared to most houses today. Cutting the leakage area in half can lead to dramatically lower heating costs and an increased level of control over house air temperature and air quality.

- Circulation fans: Circulation fans are commonplace in most houses, enabling growers to move the hot air off the ceiling down to chick level, promoting more uniform house temperatures, drier litter, lower ammonia levels and potentially reducing heating costs by 10% to 30%.

- Attic inlets: By pulling 5° F to 30o F warmer air from a house’s attic space during daylight hours, producers have found that they can ventilate their houses more during cold weather while keeping heating costs to a minimum.

- Energy-efficient tunnel fans: Over the past 3 decades, the energy efficiency ratings of tunnel fans have increased from approximately 18 cfm/watt to 25 cfm/watt, meaning the cost of moving a cubic foot of air has decreased by approximately 30%.

- Increased levels of ceiling insulation: In the 1990s, most dropped-ceiling houses typically had an R-value of 12 ft2·°F·h/BTU. Today the typical ceiling R-value has nearly doubled to 21 ft2·°F·h/BTU thereby cutting heat loss through the ceiling during cold weather roughly in half.

- LED lighting: The wide use of LED lighting has dramatically cut the cost — at least 70% — of lighting a poultry house compared to traditional incandescent lighting.

- Insulated tunnel doors: The adoption of insulated tunnel doors over tunnel-inlet curtains has not only reduced heating costs by at least 10% but also led to more uniform bird cooling when in tunnel-ventilation mode during hot weather.

- Variable-speed tunnel fans: Though only recently introduced to the poultry market, variable-speed motors on tunnel-ventilation fans have been shown to control air exchange rates more accurately and potentially reduce the cost of operating a fan by as much as 50%. Multiple field trials have shown that variable-speed tunnel fans could reduce the cost of ventilating a house by 30%, even when compared with the best modern fixed-speed exhaust fans.

- Evaporative-cooling pads: The introduction of evaporative-cooling pads has proven to help producers keep their birds cool, even during the hottest of summer days. Evaporative-cooling pads can reduce the temperature of the incoming air by 10° F to 30oF, using a fraction of the power of traditional air-conditioning systems.

- Environmental controllers: Modern poultry-house environmental controllers not only allow producers to more precisely control house temperature and air quality but also minimize the likelihood that heating and cooling equipment will operate simultaneously, preventing waste of gas and electricity.

- Radiant heaters: Roughly 50% of the heat produced by a radiant heater is in the form of radiant heat, which directly heats the floor and the birds.

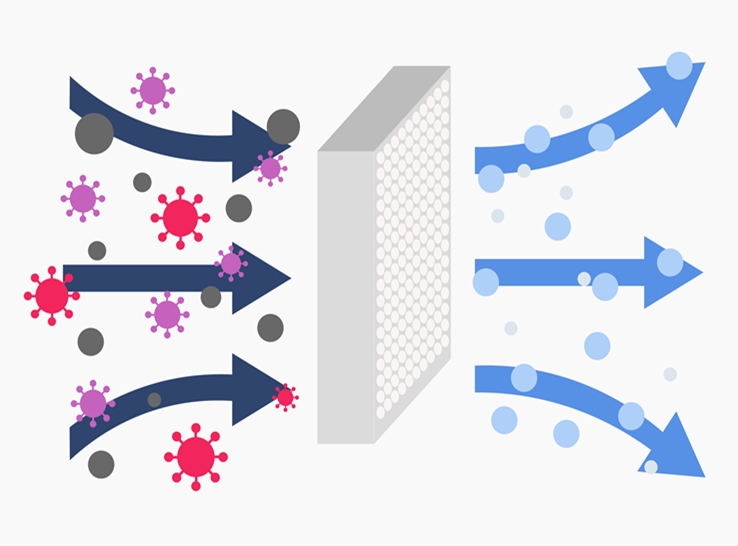

- Sidewall air inlets: The wide adoption of negative-pressure ventilation using side-wall inlets has not only significantly improved the environmental conditions for our birds during cold weather but also has lowered the cost of heating our houses. Air inlets direct the cold incoming air along the ceiling so it can be warmed by the hot air collecting near the ceiling produced by the house’s heating system and the birds.

- Tunnel ventilation: In the early 1980s, most poultry houses were curtain-ventilated during the summer. The dozen or so 36-inch fans provided a very limited amount of air movement over the hot bird. The object was to simply keep birds alive, which was often met with limited success.

The introduction of tunnel ventilation has enabled producers to keep birds comfortable and growing during even the hottest of summer days. The uniform air movement created by today’s energy-efficient tunnel-ventilation fans would not only be very difficult to create using circulation fans but would also require significantly more electricity to do so, compared to a modern tunnel-ventilation system.

Final thoughts

In conclusion, the poultry industry has long been at the forefront of implementing sustainability measures that benefit both the environment and the birds being grown. Through continual innovation and attention to efficiency, poultry producers have adopted practices that lower energy costs, reduce resource consumption and enhance conditions for their birds.

From innovative cold- and hot-weather ventilation systems and insulation upgrades to energy-saving lighting and environmentally controlled housing, the industry’s commitment to sustainable practices has grown stronger over the decades. These advancements not only reflect a dedication to responsible farming but also ensure the continued availability of affordable poultry products for consumers.