By Meghan Bowman

Data platform program manager, Ancera

The global poultry industry spends billions of dollars annually on vaccines, anti-infectives, coccidiostats, litter amendments and other tools to help ensure flock health, welfare, efficiency and performance.

Faced with rising costs, a major US poultry company recently partnered with Ancera to monitor the effectiveness of its program for controlling coccidiosis, a common protozoal disease of chickens linked to significant losses in flock performance and feed conversion.

Coccidiosis occurs when flocks ingest relatively sporulated coccidia oocysts, or eggs, which transmit coccidia to other birds. According to the Merck Veterinary Manual, both clinically infected and recovered birds shed oocysts in feces, which contaminate feed, dust, water, litter and soil. Oocysts also may be transmitted via equipment, personnel, insects and rodents.

To establish a benchmark, Ancera measured oocyst-per-gram (OPG) levels in bird feces on days 14, 21 and 28 of the grow-out cycle.

At the start of the study, the complex was using an anticoccidial treatment (Control A). After implementing a scheduled transition to another treatment (Control B), the data revealed a significant rise in coccidia oocysts, leading to performance setbacks.

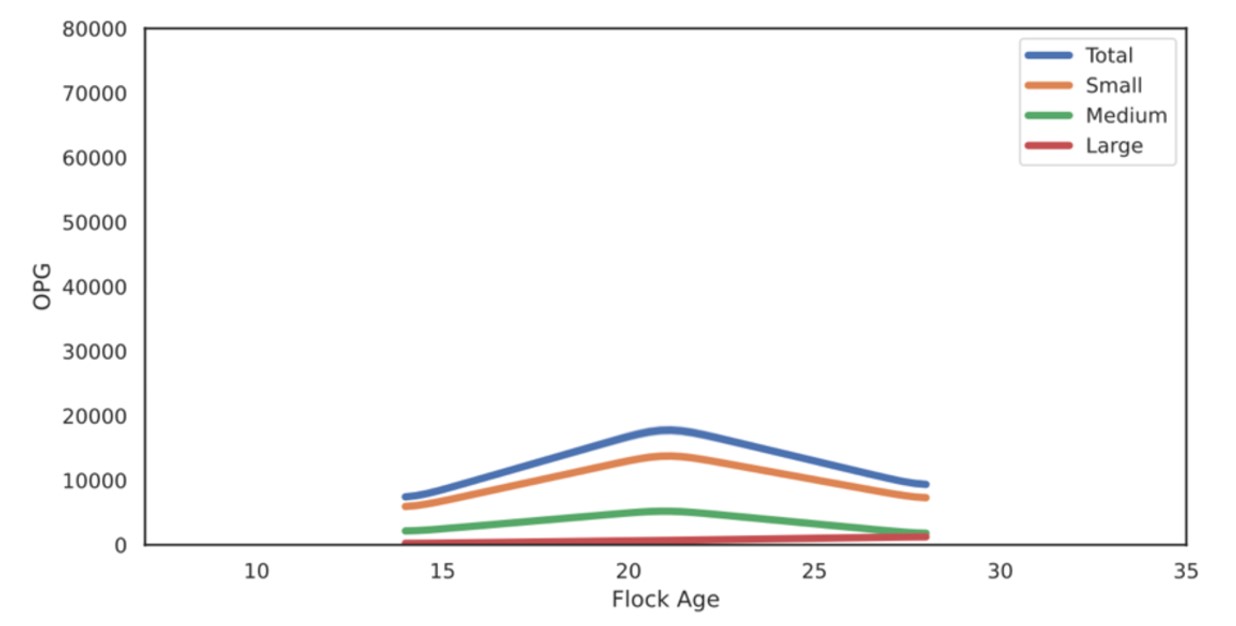

Figure 1. Complex-level OPG distribution (Control A)

In Control A, Ancera observed peak cycling on day 21, with levels diminishing on day 28.

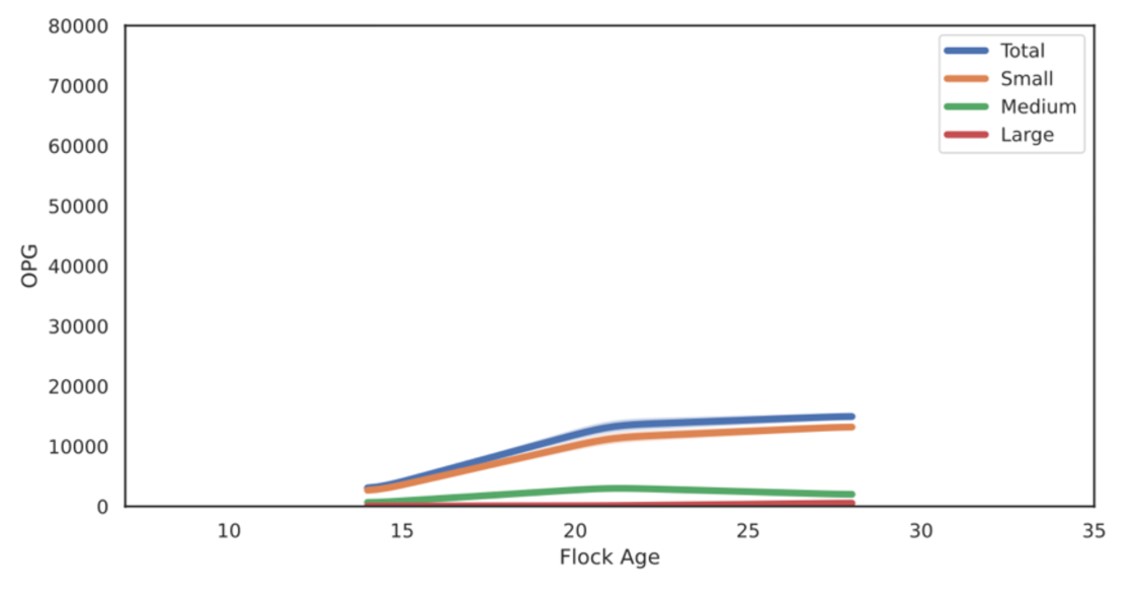

Figure 2. Complex-level OPG distribution (Control B)

In Control B, Ancera observed a late cycling pattern that may have continued even past the last monitored interval. Declines in feed conversion and weight gain were also observed, suggesting the possibility that reduced coccidia control may have been a contributing factor.

The transition to Control B led to unforeseen complications, indicated by increases in OPG levels and correlated performance metrics. Ancera determined that changing treatment plans cost the company nearly $250,000 in lost pounds sent to the plant and a 5-point hit to their feed-conversion rate.

Guessing game without data

Managing the complexities of a live-production system requires achieving an optimal balance of flock health and welfare, performance and financial returns within the limitations of the production system.

Managers rely on trial results, experience and intuition, but in the end, decisions are based largely on educated guesses. Armed with higher quality and more timely data, integrators can:

- Confidently stay on a more optimal control program.

- Change to a control program that improves performance.

- Determine whether flock performance was impacted by coccidia.

- Implement precise interventions on underperforming farms with the right tools.

Measurements in this study were based on Ancera’s Eimeria-enumeration technology. Ancera provides granular visibility into a company’s flock health with data science designed to help poultry integrators improve operational efficiency.

Editor’s note: Content on Modern Poultry’s Industry Insights pages is provided and/or commissioned by our sponsors, who assume full responsibility for its accuracy and compliance.