By Michael Czarick

Extension Specialist – Engineering

University of Georgia

Department of Poultry Science

Did you know that all published minimum ventilation recommendations for broilers could easily be off by 100% or more? They may sound precise — 1.00 cmh per kg of weight, 75 cfm/1,000 chicks, etc. — but they are merely an educated guess.

Published minimum poultry housing ventilation rates are not based on something relatively predictable, such as a bird’s oxygen requirement or even its carbon dioxide production. That’s why they aren’t very accurate. They are based on controlling house moisture levels (Figure 1). The amount of moisture a bird adds to the litter and air in a house is relatively predictable (+/- 20%), but the amount of fresh air required to remove that moisture is extremely difficult to predict accurately.

Figure 1. Moisture-laden air forming condensation clouds as it is exhausted from a house on a cold morning

The primary goal of minimum ventilation is to ensure that whatever moisture the birds add to a house each day is removed. If birds add 1,000 gallons of water to a house, a grower needs to remove 1,000 gallons of water from the house.

If exhaust fans remove less than 1,000 gallons of water, moisture levels within the house will rise, leading to damp litter and increased ammonia production (Figure 2). If a grower removes more than 1,000 gallons, the litter will become drier and dustier (Figure 3). Furthermore, higher ventilation rates associated with the increased moisture removal from the house will result in higher heating costs.

Figure 2. When moisture levels in litter are relatively low, so are ammonia levels.

Figure 3. If more than 1,000 gallons of water is removed, litter can become drier and dustier.

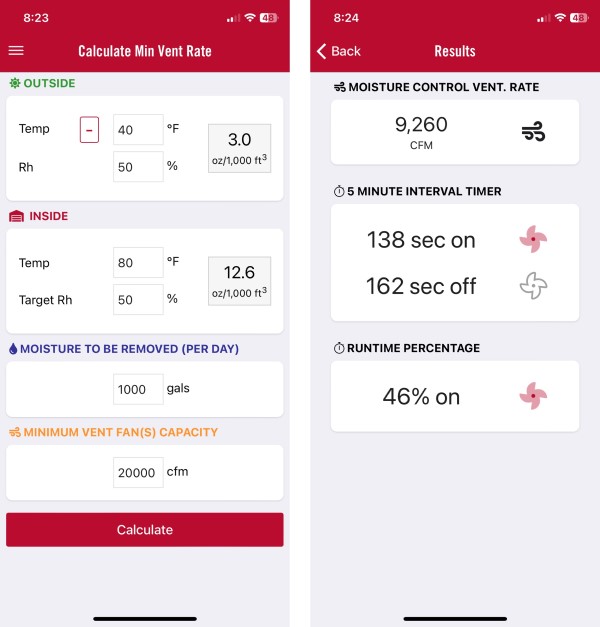

The amount of air that needs to be exchanged to remove moisture that birds add to the house varies with inside/outside conditions. Say the outside temperature is 40o F, and the relative humidity (RH) is 50%. In this case, a minimum ventilation rate of approximately 9,300 cfm would be required to remove 1,000 gallons of water (80o F and RH is 50%) (Figure 4). That’s according to Poultry411’s Minimum Ventilation Calculator app.

Figure 4. The Poultry411 app

If the weather is a mild 65o F/50% RH, the minimum ventilation rate would need to nearly double — to 17,500 cfm — to remove the same 1,000 gallons of water. If outside humidity were to increase to 70%, the minimum ventilation rate would have to be more than doubled again — to 44,500 cfm.

Complicating factors

There are complicating factors to consider. The inside/outside temperature and humidity aren’t constant. They change over the course of a day, and the amount of moisture being removed from a house is constantly changing even if the required minimum ventilation rate remains the same.

The effectiveness of a house’s minimum ventilation system also will affect how much air needs to be exchanged to remove moisture added by birds. The calculations used to determine minimum ventilation rates for moisture control assume that all the fresh air enters through a house’s air-inlet system and is perfectly mixed with the air throughout a house. However, cool air that enters through cracks will quickly fall to the floor; it will not remove as much moisture as air that enters through a house’s inlet system, which is warmed and dried by the air that collects near the house ceiling.

As the percentage of air that enters through the cracks increases, the amount of moisture removed by each cubic foot of air exchanged declines. You need to increase the minimum ventilation rate to effectively remove moisture that birds add daily to a house.

Simple tool measures humidity

At best, any recommended minimum ventilation rate is a very rough starting point. But if growers keep in mind that the goal of minimum ventilation is to control house moisture levels, it becomes clear they don’t need a minimum ventilation chart. They simply need a tool that will measure house moisture levels to determine if their minimum ventilation rates need to be increased, decreased or remain the same.

If moisture levels are high, minimum ventilation rates need to be increased. If house moisture levels are low, minimum ventilation rates need to be decreased. It’s really not that different from ventilating to control house temperature, which growers do not by using a chart, but by using thermostats and environmental temperature-controller sensors. If the temperature is too high, they need to ventilate more. If it is too low, they need to ventilate less.

The tool required to monitor house moisture levels is a simple humidity sensor. The ideal RH is between 40% and 60%. If it is below 40%, too much moisture may be being removed from the house by the fans, and the litter will become excessively dry and dusty. If it is above 60%, chances are too little moisture is being removed from the house, and over time, the litter will likely become damp and excess ammonia may become an issue.

Though controlling RH is the primary factor we need to manage, especially during cold weather, growers still need to be concerned about other air-quality variables such as carbon dioxide and ammonia. The best way to determine whether minimum ventilation rates are sufficient for controlling humidity and other potentially harmful air-quality variables isn’t with charts and apps — it’s by measuring them. The good news is that growers will find that the vast majority of the time, ammonia and carbon dioxide levels will rarely be an issue with sufficient control of RH.

Editor’s note: The opinions and/or recommendations presented in this article belong to the author and are not necessarily shared by Modern Poultry.