By Michael Czarick

Extension Specialist – Engineering

University of Georgia

Department of Poultry Science

How many light bulbs does it take to light a 54′ x 500′ broiler house?

It depends on the desired light intensity, how much light the light bulbs produce (lumens) and how uniform you want your light levels. You can install a lot of low-lumen light bulbs — say 200, 6-watt, 500-lumen bulbs — and get very uniform light intensity, but the initial cost will be high. Or you could install far fewer high-lumen output bulbs — 67, 18-watt,1,500-lumen bulbs — with a lower initial cost but much more variation in floor light intensity.

Both systems will produce the same total amount of light and the average floor light levels will be the same, but the house with fewer light bulbs will have significantly more variation in light intensity. Some locations will have too much light, while others will not have enough (Figure 1).

Figure 1. An example of poor light distribution

Radiant heating challenges

The installation of radiant heaters in broiler houses presents a similar challenge. In general, the brooding area of most poultry houses requires a heating system capable of providing between 40 and 60 BTUs per hour to maintain an air temperature in the low 90°s during cold weather.

Take, for instance, a 54′ x 250′ brooding area. It could require a heating system capable of producing approximately 675,000 BTUs per hour (54′ x 500′ x 50 BTUs per hour = 675,000 BTUs per hour). A producer could opt for 13, 50,000 BTUs per hour, 20′ long radiant tube heaters or 8, 20′ long, 90,000 BTUs per hour radiant tube heaters.

Both systems would be capable of generating the same air temperature on a cold morning, and the average floor temperature would be similar. However, uniformity of the floor temperature would be significantly different. The house with fewer radiant tube heaters would have some floor areas where the temperature is too hot for chicks and other floor areas further from tube heaters where the temperatures could be too cool. The house with the greater number of heaters would likely cost more, but the floor temperatures would tend to be far more uniform.

Houses need sufficient BTUs, floor coverage

When designing a radiant heating system, it’s important to ensure there are enough BTUs to maintain the proper house temperature during cold weather and that the radiant heaters to be installed will effectively distribute the radiant heat relatively evenly throughout the brooding area. It doesn’t have to be perfectly uniform, but a small gradient in floor temperatures is desirable so chicks can choose from a variety of floor temperatures that best meet their needs.

Smaller, possibly weaker chicks might want slightly higher floor temperatures, while larger, faster-growing chicks need slightly lower floor temperatures. That being said, it is generally unnecessary to have areas of the house with floor temperatures much above 100o F. Chicks tend to avoid these areas because it is simply too hot for them. In addition, having excessive hot spots will tend to reduce the overall heating efficiency of a house because heating the floor more than needed is simply wasteful.

Illustrating the point

Currently, University of Georgia poultry scientist and professor Brian Fairchild, PhD, and I are conducting a study on a commercial broiler farm to examine how improved radiant heat distribution could affect chick comfort and heating costs. All four houses were equipped with a similar brooding-area heating capacity (560,000 versus 640,000 BTUs per hour). The primary difference between the houses was the length of tube heaters used.

Two houses were equipped with 7, 20′ long (80,000 BTUs per hour) radiant tube heaters installed along the centerline of the brooding area, while the two other houses were equipped with 8, 40′ long (80,000 BTUs per hour) tube heaters installed in two rows of four, approximately 18′ from each side wall.

The 40′ tube heaters (SRP ALTX80) used in the study were selected in part due to their ability to distribute radiant heat evenly along the tube length, which has traditionally been a challenge with some longer tube heaters. By spreading the same 80,000 BTUs per hour of heat along a tube twice as long, the 40′ tube heaters didn’t tend to generate excessive floor temperatures underneath. This allowed tube heaters to be installed within 6 feet of the outer feed lines and 2 feet from the second row of drinker lines without fear of running chicks off feed and water during cold weather.

Positioning advantages

Positioning the two rows of “low intensity” tube heaters closer to the side wall had several advantages:

- It put more radiant heat on the litter in an area of the house where excessive litter moisture tends to be more problematic.

- It placed tube heaters closer to the cold incoming from side-wall inlets, which quickened heating on its way to the center of the house.

- It helped warm and cool air leaking in through cracks in side walls more quickly during cold weather compared to radiant heaters installed along the center line of the house.

Preliminary results from this recent study underscore the benefits of a well-designed radiant heating system in broiler houses. The use of two rows of low-intensity radiant heaters proved to be more effective in creating uniform floor temperatures during brooding.

On cold mornings, chicks in the house with the 20′ tube heaters tended to avoid the center of the house. In contrast, the chicks in the house with the 40′ tube heaters were more evenly distributed from wall to wall and did not tend to avoid the areas directly under the tube heaters.

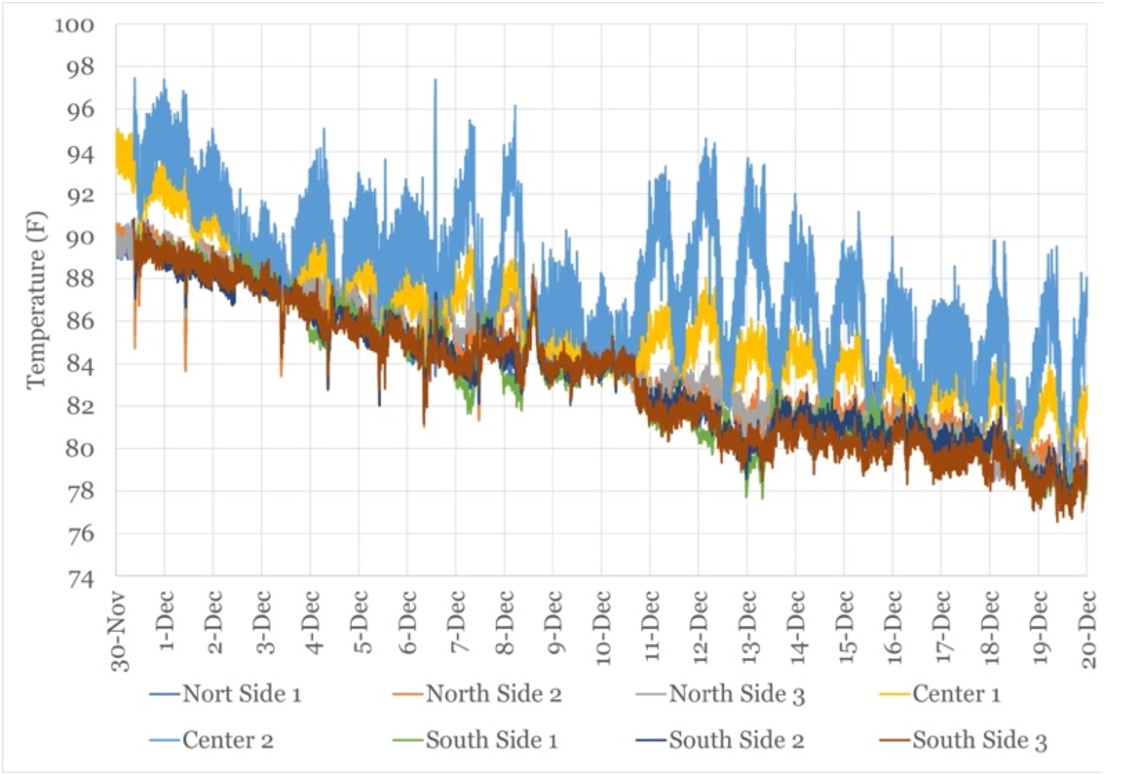

Temperature-data loggers positioned along the two outside feed lines and the inside drinker lines showed that, during brooding, temperature variations were typically less than 5o F in the house with the 40′ tube heaters but were often 10o F to 15o F in the houses with 20′ tube heaters (Figures 2 and 3).

Figure 2. Temperatures in houses with 40’ tube heaters

Figure 3. Temperatures in houses with 20’ tube heaters

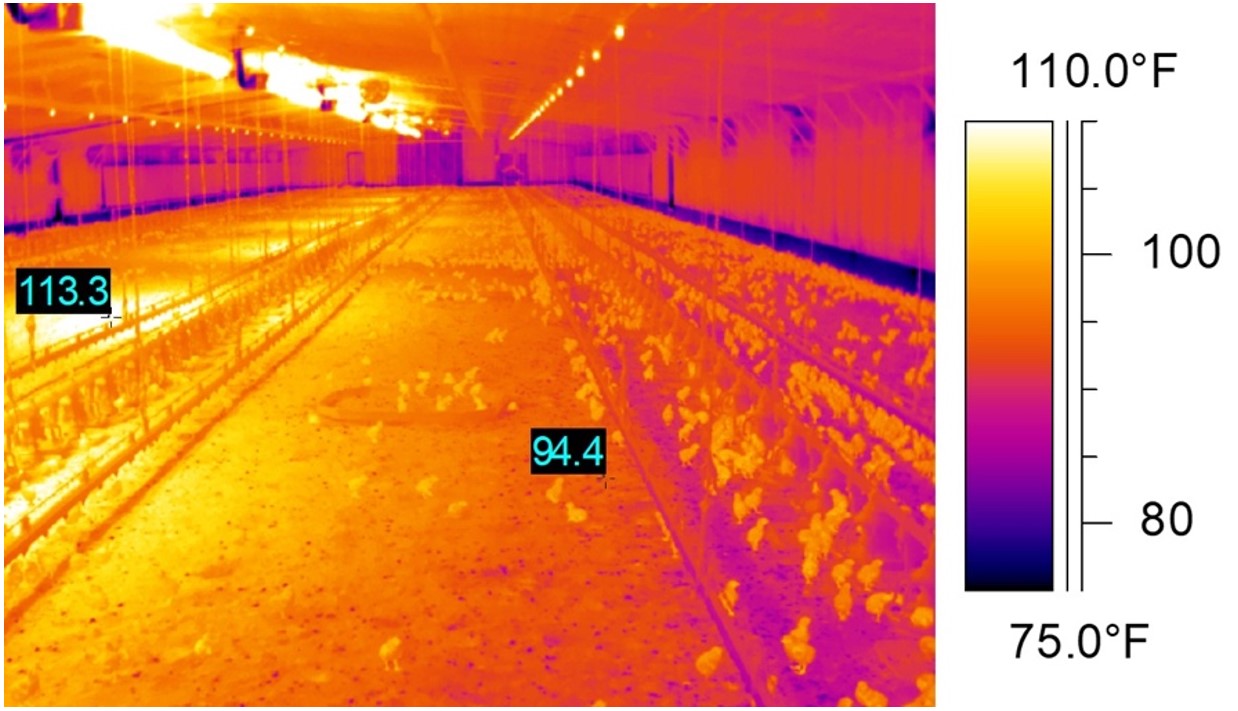

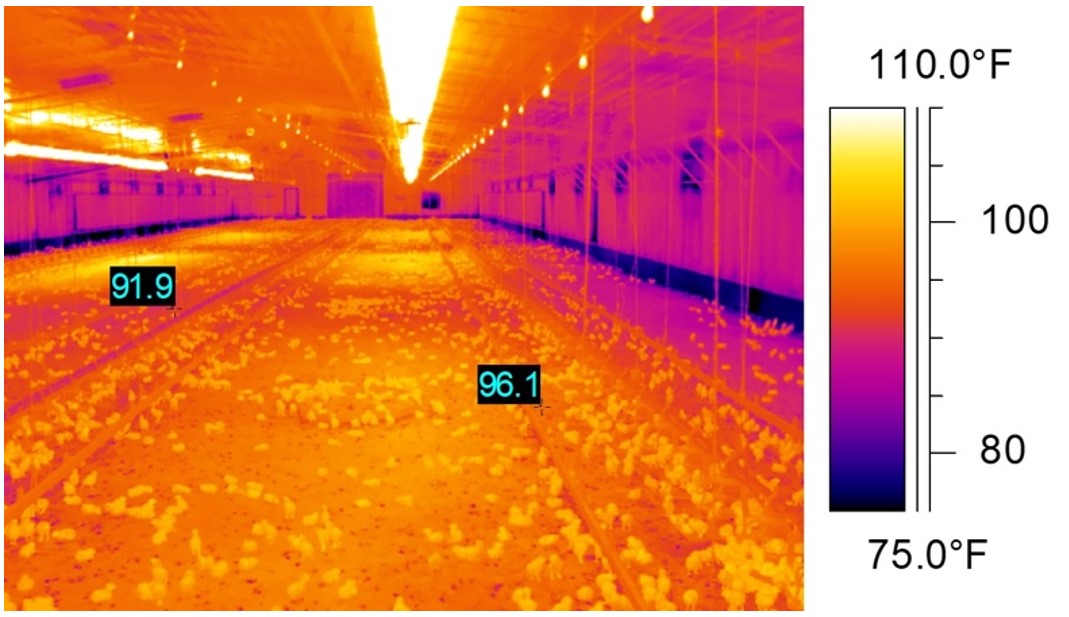

Thermal images taken in the houses during brooding revealed that a significant portion of floor temperatures in the center of the houses with the 20′ tube heaters was over 100o F (Figures 4 and 5), whereas floor temperatures in houses with the 40′ tube heaters were far more uniform and rarely exceeded 95o F, even directly beneath the heaters.

Though the results from the study are very preliminary, it is clear that improving radiant heat distribution can be beneficial. More uniform floor and air temperatures have resulted in improved chick distribution during brooding and slightly lower heating costs. Additional work may reveal other advantages such as dryer litter, lower ammonia levels, improved paw health and potential fuel savings.

Figure 4. Temperatures in the center of houses with 20’ tubes were over 100o F

Figure 5. Temperatures in the center of houses with 40’ tubes rarely exceeded 95o F

Editor’s note: The views expressed in this article are solely those of the author.