Machine-learning approaches are providing new insight into bird comfort during loading and transportation, which could reduce losses due to overheating.

University of Georgia research is using computational simulations to create a machine-learning model to evaluate bird comfort during loading, transportation and holding prior to processing.

The goal is to create an app that will allow farmers and transporters to evaluate conditions — including air velocity, heat production, ambient temperature and relative humidity — before transport and implement redesigned fan systems to improve airflow and reduce heat stress among the chickens.

In Georgia and surrounding areas, high temperatures and humidity can account for 2% to 3% in losses during transportation, impacting farmers’ profits.

From modelling to data collection

So far, the research team has developed a machine-learning model to analyze variables including air velocity, broiler heat production, ambient temperature and relative humidity to predict the conditions for the comfort and welfare of the birds.

The next steps of the study, funded by a $600,000 Agriculture and Food Research Initiative (AFRI) grant from USDA’s National Institute of Food and Agriculture, are to build a model crate — constructed using standard materials used by the poultry industry — and equipping it with sensors to measure wind speed and direction, temperature and relative humidity.

These sensors, which will be installed at 24 points inside the crate, will provide real-time measurements of simulated conditions during transport using live birds in the lab and the data will be used to design fans and determine optimal fan placement during loading and transport to improve bird welfare.

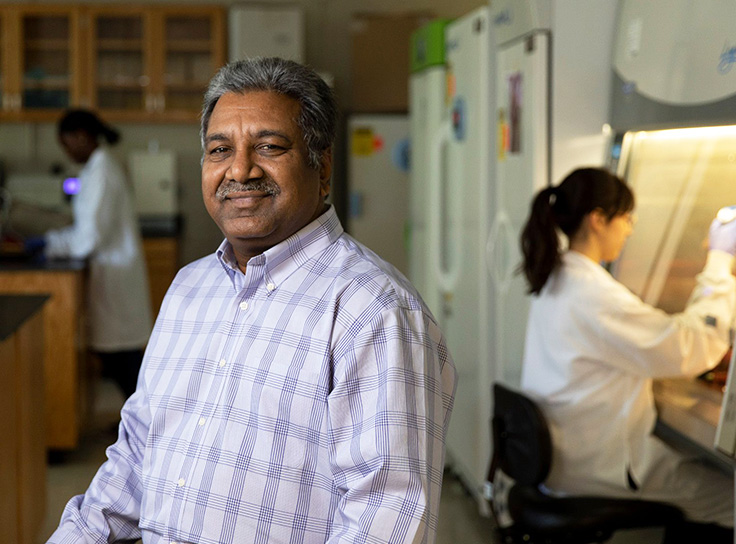

“Before we do validations on the farm, we will conduct more lab experiments on the small coop model to calculate temperature, body heat, humidity and airflow and measure how the birds react and what changes occur in body temperature under controlled environment,” said Harshavardhan Thippareddi, PhD, Professor in Poultry Science.

Addressing a complex issue

Computational modeling and simulation are a perfect fit for the research, said Ramana Pidaparti, PhD, professor in UGA’s College of Engineering and a specialist in aeronautics and astronautics, who is also involved in the work.

The microenvironment of poultry coops presents a complex problem, he noted, and while initial studies will focus on single coops, additional work will involve a multi-coop model simulating the conditions on transport trucks.

“With these simulations, we will try to identify the static zones within the poultry transportation coops where airflow through the loaded trailers is limited, with the goal of designing fan systems and targeting those static zones so it results in well-ventilated systems to improve comfort level,” Pidaparti said. “We are trying to make minimal changes based on the existing practices in the poultry industry that would achieve maximum impact in reducing heat stress in birds.”

Based on the data from the simulations, the model will be used to “fine tune” the artificial intelligence model to have predictive capability, Pidaparti said.

“Our idea is to create an app that people can dial in the environmental factors and see what the conditions will be for the birds, then optimize fan settings in such a way that maintains the welfare of the birds,” he added.

Thippareddi said the tool will allow producers and processors to develop handling protocols for birds based on the level of risk to the birds based on current environmental factors.

“This is a truly an interdisciplinary collaboration, harnessing UGA’s strengths in engineering and poultry science together to solve an important problem for the poultry industry,” he said.

Photo: Andrew Davis Tucker, University of Georgia Marketing and Communications